AI is transforming the manufacturing industry, revolutionizing predictive maintenance, quality control, production optimization, supply chain management, and workplace safety. CloudApper's AI platform offers customizable solutions to help manufacturers leverage AI effectively and gain a competitive edge in the industry.

AI (Artificial Intelligence) has emerged as a transformational force in a variety of industries, including the industrial industry. AI is transforming the industrial business with its capacity to analyze massive volumes of data, automate procedures, and optimize operations. In this post, we will look at how is AI transforming the manufacturing industry and how CloudApper’s AI platform is contributing to this transition.

Predictive maintenance is one of the core areas where AI is having a substantial influence in manufacturing. Traditional maintenance techniques frequently adhere to a strict timetable, resulting in needless downtime and expenses. However, AI-powered predictive maintenance analyzes real-time historical data collected from the field using artificial intelligence. AI can forecast when a machine is likely to malfunction and plan maintenance in advance by detecting trends and abnormalities. This method not only avoids unnecessary downtime, but it also increases operational efficiency and cost savings. CloudApper’s AI platform provides industrial organizations with tailored predictive maintenance solutions, allowing them to streamline their maintenance operations and enhance equipment uptime.

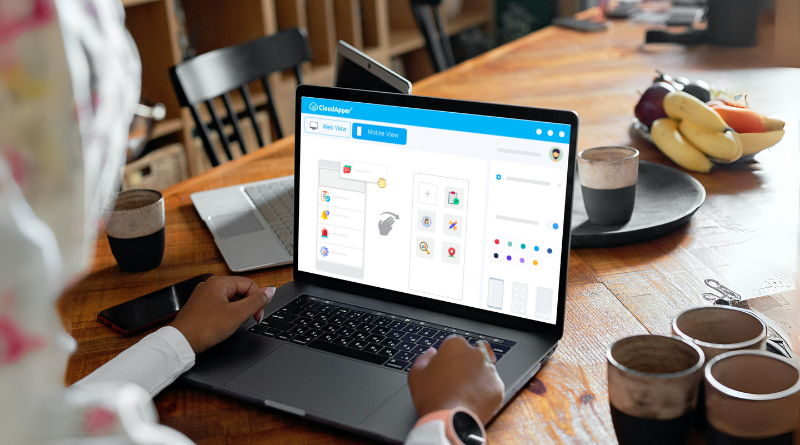

CloudApper AI eliminates the need for extensive coding and reliance on scarce developer talent, allowing manufacturers to quickly and cost-effectively implement custom solutions without the traditional software development challenges.

Quality control is another area where AI is transforming industry. Manual inspection is used in traditional quality control procedures, which may be time-consuming, subjective, and error-prone. Deep learning-powered AI-based systems can assess data collected during the manufacturing process of each item on the production line in real time. This enables automatic fault identification, which ensures that only high-quality items reach the market. CloudApper’s AI platform offers customisable quality control solutions, assisting manufacturers in improving product quality, reducing errors, and increasing customer happiness.

AI is also propelling breakthroughs in manufacturing optimization. Manufacturers can use AI algorithms to examine complicated production data, such as past production records, downtime data, and environmental conditions, in order to uncover improvement possibilities. AI may enhance overall efficiency by optimizing manufacturing schedules, reducing energy use, and reducing energy consumption. CloudApper’s AI platform provides production optimization solutions to manufacturers, allowing them to make data-driven choices and optimize their operations for optimal efficiency and profitability.

CloudApper AI’s predictive maintenance solutions leverage machine learning algorithms to analyze real-time data, enabling proactive identification of potential equipment failures and optimizing maintenance schedules, reducing downtime and maximizing operational efficiency.

Another area where AI is bringing about dramatic change is supply chain management. To optimize supply chain operations, AI algorithms can examine enormous amounts of data, such as supplier performance, demand patterns, market trends, and external influences. AI-powered demand forecasting assists firms in more precisely anticipating market demand, allowing them to change production plans and inventory levels accordingly. CloudApper’s AI platform provides adaptable supply chain management solutions that use AI technology to improve inventory management, reduce lead times, and improve supply chain visibility.

Furthermore, AI is playing an important role in improving industrial job safety. AI-powered systems can monitor the manufacturing floor in real time and identify possible safety issues. AI systems, for example, may identify workers who are not trained to carry out risky tasks or identify actions taken during the job that could lead to accidents. AI assists manufacturers in creating a safer working environment for their employees by giving quick alerts and notifications. CloudApper’s AI platform provides workplace safety solutions that use AI technology, allowing manufacturers to solve safety problems and prevent accidents before they occur.

CloudApper AI optimizes production schedules, analyzes complex production data, and leverages AI algorithms to enhance supply chain management. By improving production efficiency, minimizing energy consumption, and optimizing inventory management, manufacturers can achieve higher productivity and profitability.

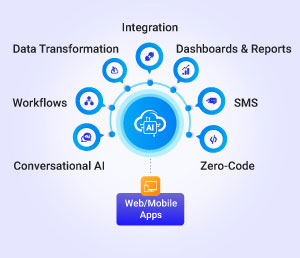

CloudApper’s AI platform, in addition to these specific applications, offers a wide range of configurable solutions to satisfy the unique demands of industrial firms. The platform’s adaptability enables the creation of AI-powered solutions for a wide range of use cases, including inventory management, equipment optimization, process automation, and supply chain analytics. Manufacturing firms may use CloudApper to use the potential of AI to streamline processes, enhance productivity, decrease costs, and achieve a competitive advantage in the market.

The advantages of using AI in the industrial business are substantial. Among the benefits are increased operating efficiency, decreased downtime, improved product quality, streamlined supply chain management, and increased worker safety. CloudApper’s AI platform serves as a catalyst in this shift, giving industrial organizations the tools and technology they need to properly harness AI and realize its full potential.

AI is To summarize, artificial intelligence (AI) is disrupting the manufacturing business by transforming different parts of operations such as predictive maintenance, quality control, production optimization, supply chain management, and workplace safety. CloudApper’s AI platform is critical to this change because it provides customisable solutions that use AI technology to solve the specific demands of industrial organizations.

Manufacturers may proactively plan maintenance, decrease downtime, and enhance operational efficiency by leveraging CloudApper’s AI-powered predictive maintenance solutions. The adaptable quality control systems allow for automatic flaw identification, guaranteeing that only high-quality products reach the market and increasing customer satisfaction.

Manufacturers may use CloudApper‘s production optimization tools to make data-driven choices, optimize production schedules, reduce energy usage, and enhance overall efficiency. The platform’s adaptable supply chain management solutions use AI algorithms to optimize inventory management, precisely estimate demand, and improve supply chain visibility.

What is CloudApper AI Platform?

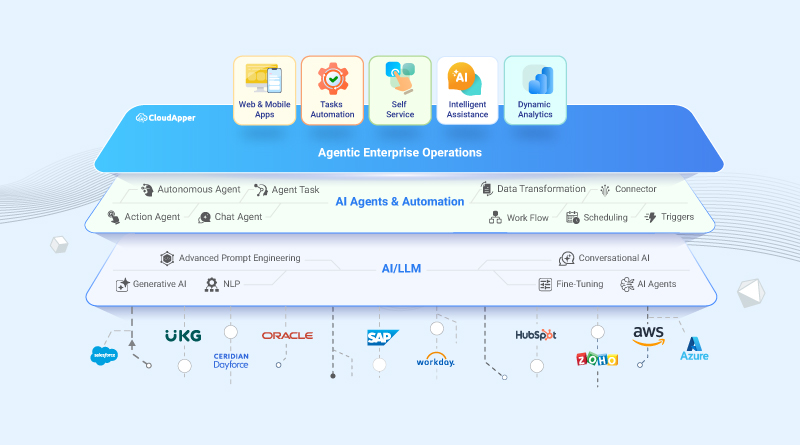

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More

Brochure

CloudApper hrPad

Empower Frontline Employees with an AI-Powered Tablet/iPad Solution

Download Brochure

CloudApper AI Solutions

- Works with

- and more.

Similar Posts

Beyond Developers: How AI Agents Drive Profitability Across the Enterprise

How AI DevAgents Are Minimizing Friction in the Software Development…