Hiring fast, accurate warehouse picker-packers? These 10 targeted interview questions quickly reveal experience, speed, attention to detail, and safety habits. Even better—AI can now ask them automatically via text, screen hundreds of applicants 24/7, and only send you the best fits.

Table of Contents

TL;DR

Hiring reliable warehouse picker-packers is tough. Ask these 10 proven interview questions to spot speed, accuracy, safety mindset, and culture fit fast. Bonus: CloudApper AI Recruiter can auto-ask them 24/7 via text/WhatsApp inside Workday, Dayforce or UKG — cutting screening time by 80%.

For more information on CloudApper AI Recruiter visit our page here.

Hiring Warehouse Workers and Picker-Packers has become one of the most pressing challenges facing manufacturing and logistics operations today. The warehouse industry is experiencing unprecedented growth—e-commerce expansion alone has driven warehouse employment up 20% in recent years—yet finding qualified workers remains incredibly difficult. The average time-to-hire for warehouse positions now exceeds 35 days, with cost-per-hire climbing to $1,600 when factoring in recruiting, onboarding, and productivity losses during chronic understaffing.

The talent shortage is acute and worsening. According to industry workforce reports, warehousing and logistics operations report vacancy rates of 8-12%, with some facilities operating 15-20% below optimal staffing levels during peak seasons. Meanwhile, turnover rates hover around 40-50% annually in many operations, creating a constant cycle of recruiting, hiring, training—only to start over when workers leave within months.

But here’s the crisis that’s truly crippling warehouse operations: extreme candidate drop-off and no-shows. Research shows that approximately 60-70% of warehouse job applicants either abandon the hiring process before completion or fail to show up for their first day. Traditional hiring approaches—delayed responses, phone tag for scheduling, lengthy applications—simply don’t work for the hourly workforce that warehouses depend on. When candidates are applying to multiple facilities and accepting the first offer they receive, speed isn’t just important—it’s everything.

The role itself has also evolved significantly. Today’s Warehouse Workers aren’t just moving boxes—they’re operating warehouse management systems (WMS), using RF scanners and handheld devices, working with automated storage and retrieval systems (AS/RS), managing inventory accuracy through technology, and adapting to robotics and automation on the warehouse floor. They need physical capability, attention to detail, tech literacy, and safety awareness that goes far beyond traditional warehouse work.

Enter CloudApper AI Recruiter: our conversational AI chatbot that revolutionizes warehouse hiring. It engages candidates instantly via SMS or web chat—critical for hourly workers who check texts but rarely monitor email—conducts intelligent screening interviews 24/7, assesses physical capability and reliability indicators, and eliminates up to 90% of manual screening work while removing unconscious bias. Whether someone applies at midnight after their current shift or Sunday morning during job searching, our AI responds immediately and keeps them engaged through the entire process.

In this guide, we’ll give you the exact interview questions you need to identify reliable, capable Warehouse Workers and Picker-Packers who’ll show up consistently and perform quality work. Then we’ll show you how CloudApper AI Recruiter handles the heavy lifting, transforming your hiring timeline from weeks to days while dramatically reducing no-shows and early turnover.

Why These Questions Matter for Warehouse Workers & Picker-Packers

The Warehouse Worker and Picker-Packer roles have transformed from purely manual labor to tech-enabled, process-oriented positions that directly impact inventory accuracy, order fulfillment speed, and customer satisfaction. Today’s warehouse professionals are operating sophisticated warehouse management systems, using RF scanning technology for real-time inventory tracking, following precise picking methodologies (zone picking, wave picking, batch picking), working alongside robotic systems, and maintaining the accuracy standards that drive successful e-commerce and distribution operations.

They’re navigating environments with strict safety protocols, operating powered industrial equipment (pallet jacks, order pickers, sometimes forklifts), meeting productivity metrics and quality standards, working various shifts including nights and weekends, and adapting to seasonal volume fluctuations that can triple workload during peak periods. In modern fulfillment centers, they’re also interfacing with automation—picking to light systems, voice-directed picking, automated sortation systems—requiring comfort with technology that didn’t exist in traditional warehousing.

Old-school questions like “Can you lift 50 pounds?” or “Are you available for overtime?” barely scratch the surface. You need to assess reliability and attendance history (the #1 predictor of success), comfort with warehouse technology and learning systems, attention to detail and quality orientation, safety awareness and adherence to protocols, ability to meet productivity standards, physical stamina and proper lifting techniques, problem-solving when issues arise, and adaptability to changing procedures and seasonal demands.

With warehouse turnover consistently topping 40-50% annually, and with understaffing directly impacting fulfillment speed, order accuracy, and customer satisfaction, asking the right questions upfront isn’t optional—it’s operationally critical. A reliable, accurate warehouse worker who shows up consistently is worth their weight in gold; a poor hire who calls out frequently, makes errors, or quits within weeks costs you far more than wages in training investment, productivity losses, and operational disruption. These questions will help you identify candidates who possess the work ethic, capability, and realistic understanding to succeed in modern warehouse environments.

Top 10 Crucial Warehouse Worker & Picker-Packer Interview Questions (With Sample Strong Answers)

1. Describe your experience with warehouse work. What types of tasks have you performed, and what warehouse technology have you used?

Why ask this?

This reveals relevant experience, familiarity with warehouse operations, and comfort with technology—essential for minimizing training time and ensuring productivity.

Sample Strong Answer:

“I’ve worked in warehousing for three years, mostly in e-commerce fulfillment. I’ve done receiving, put-away, order picking, packing, and shipping. I’m experienced with RF scanners—I use them to locate items, confirm picks, and update inventory in real-time. I’ve worked with conveyor systems and automated sorting equipment. I’m also comfortable with warehouse management systems; in my last job, we used Manhattan WMS for order management. I understand the importance of scan accuracy because one mistake can send the wrong product to a customer or throw off inventory counts. I’ve consistently met or exceeded productivity targets while maintaining over 99% accuracy.”

2. Walk me through your approach to picking an order. How do you ensure accuracy while maintaining speed?

Why ask this?

This tests understanding of proper picking methodology, quality orientation, and ability to balance speed with accuracy—core competencies for warehouse success.

Sample Strong Answer:

“I start by reviewing the pick list on my RF scanner to understand the order and plan my route efficiently through the warehouse. As I pick each item, I verify the SKU, description, and quantity carefully—I scan the barcode to confirm it’s correct rather than just grabbing what looks right. If I’m unsure, I double-check the location and item rather than guessing. I place items in totes or on pallets organized by order to prevent mixing. Once the pick is complete, I do a final count before moving to packing or staging. Speed comes from knowing the warehouse layout and working efficiently, but accuracy always comes first because fixing errors later wastes more time than being careful upfront. In my last role, I maintained 140% of standard productivity while keeping accuracy above 99.5%.”

3. Tell me about your experience with safety in warehouse environments. How do you stay safe while working?

Why ask this?

Safety is paramount in warehouses. This assesses knowledge of safety protocols, personal responsibility, and situational awareness.

Sample Strong Answer:

“Safety is my top priority because warehouse environments have real hazards. I always wear required PPE—steel-toed boots, high-visibility vest, and gloves when handling rough materials. I use proper lifting techniques—bending at the knees, keeping loads close to my body, and asking for help with awkward or heavy items rather than risking injury. I’m trained on powered equipment like pallet jacks and follow all operational procedures. I stay alert to my surroundings—watching for forklifts, keeping clear of conveyor systems, and never taking shortcuts that compromise safety. I also report hazards immediately, whether it’s a spill, damaged equipment, or blocked emergency exits. I’ve worked over two years with zero safety incidents because I take it seriously.”

4. How comfortable are you with meeting productivity standards and working in a metrics-driven environment?

Why ask this?

Modern warehouses operate on measurable productivity targets. This reveals understanding of performance expectations and comfort with accountability.

Sample Strong Answer:

“I’m very comfortable with productivity metrics—I actually like having clear goals to work toward. I understand that warehouses run on efficiency, and meeting standards keeps operations running smoothly and customers happy. In my previous role, our target was 150 units per hour for picking, and I consistently averaged 165-180 while maintaining quality. I track my own performance throughout the day so I know if I need to pick up the pace. I see metrics as feedback, not pressure—they help me improve. I also understand that accuracy matters as much as speed, so I balance both. I’ve never viewed productivity standards as unreasonable; they’re usually very achievable if you stay focused and work efficiently.”

5. Describe a time when you encountered a problem during your work—maybe a wrong item, damaged product, system error, or inventory discrepancy. What did you do?

Why ask this?

Problem-solving and communication are essential. This tests initiative, accountability, and judgment when issues arise.

Sample Strong Answer:

“I was picking an order and the RF scanner directed me to a location, but when I arrived, the item wasn’t there. Instead of just skipping it or grabbing something that looked similar, I first double-checked the location label to make sure I was in the right spot. Then I checked nearby locations in case it was misshelved. When I couldn’t find it, I immediately notified my supervisor and updated the system to show the discrepancy. The supervisor had me check another location where overflow was stored, and we found it there. I completed the pick accurately, and the inventory team corrected the location data so the next person wouldn’t have the same issue. The key is not ignoring problems or making assumptions—communicate and resolve them properly.”

6. How do you handle the physical demands of warehouse work—standing for long periods, lifting, repetitive motions, working in temperature extremes?

Why ask this?

Physical capability and realistic understanding of job demands are essential. This reveals whether candidates know what they’re signing up for.

Sample Strong Answer:

“I understand warehouse work is physically demanding, and I’m prepared for that. I’ve worked jobs where I’m on my feet for 8-10 hours, and I stay in good enough shape to handle it. I wear supportive footwear and take care of my body—stretching before shifts, staying hydrated, and using proper techniques to prevent injury. I’ve worked in warehouses with no climate control, so I’m used to hot summers and cold winters—you dress appropriately and stay hydrated. I also understand that warehouse work involves repetitive motions like scanning, lifting, and reaching, and I pace myself to sustain performance over the full shift. I’ve never had issues with the physical demands because I take care of myself and use proper body mechanics.”

7. Tell me about your attendance and reliability at previous jobs. How do you ensure you’re at work on time and ready to start your shift?

Why ask this?

Attendance is the single most critical factor for warehouse success. This question directly addresses reliability—make or break for these roles.

Sample Strong Answer:

“Reliability is extremely important to me because I know warehouse operations depend on everyone showing up. At my last job, I had perfect attendance for over a year—no call-outs, no late arrivals. When I did have to miss work once for a family emergency, I called as soon as I knew, which was several hours before my shift, giving them time to adjust. I ensure reliability by having good transportation—I maintain my vehicle and have backup plans if something goes wrong. I also manage my schedule responsibly and plan ahead for appointments so they don’t conflict with work. I arrive 10-15 minutes early for my shift so I’m clocked in, have my equipment, and am ready to work exactly when my shift starts. Warehouses run on schedules, and being reliable is just part of being professional.”

8. How do you maintain focus and quality when performing repetitive tasks for hours at a time?

Why ask this?

Warehouse work involves sustained repetitive activity. This reveals mental approach, work ethic, and ability to maintain standards.

Sample Strong Answer:

“I stay focused by setting small goals throughout my shift—like ‘I’ll complete these 10 orders before break’ or ‘I’ll finish this pallet in the next 30 minutes.’ Breaking the work into chunks makes it feel less monotonous. I also take pride in accuracy—even though picking is repetitive, I challenge myself to maintain perfect scans and zero errors. I stay mentally engaged by thinking about how my work affects the customer experience; every order I pick correctly means someone gets exactly what they ordered on time. I also stay physically engaged by maintaining good pace and energy. Honestly, I don’t mind repetitive work—I find it kind of meditative, and I like seeing the tangible results of completing orders at the end of my shift.”

9. Are you comfortable working various shifts, including nights, weekends, and overtime during peak seasons?

Why ask this?

Schedule flexibility is often essential in warehousing. This assesses realistic availability and willingness to meet operational needs.

Sample Strong Answer:

“Yes, I’m flexible with scheduling. I understand warehouses often operate 24/7 and need coverage across all shifts. I’ve worked night shifts before and actually prefer them in some ways—less traffic, slightly higher pay differential, and I’m naturally more alert at night. I’m also available for weekends and understand that retail peak seasons like holidays require overtime and extra shifts. I’m looking for steady work with consistent hours, so I’m happy to commit to whatever schedule you need. Just give me advance notice when possible for shift changes, and I’ll make it work. I know schedule reliability is as important as showing up—if you need me on second shift Tuesday through Saturday, I’ll be there every week.”

10. Why are you interested in warehouse work, and what would make you stay with our company long-term?

Why ask this?

This reveals motivation, realistic expectations, and retention potential—critical in high-turnover environments.

Sample Strong Answer:

“I’m interested in warehouse work because I like active, hands-on jobs where I can see the results of my efforts. I’m good at detail-oriented work, I’m reliable, and I enjoy being part of a team that keeps operations running smoothly. I’m not looking for temporary work—I want to find a company where I can build a career. What would make me stay long-term is fair treatment, respect from management, opportunities to learn new skills and potentially advance—whether that’s operating equipment, training new employees, or moving into lead roles—and consistent hours with dependable pay. I also value working somewhere that prioritizes safety and invests in their employees. If those things are in place, I’m the type of person who stays and grows with a company rather than jumping around.”

How CloudApper AI Recruiter Makes Hiring Warehouse Workers & Picker-Packers Effortless

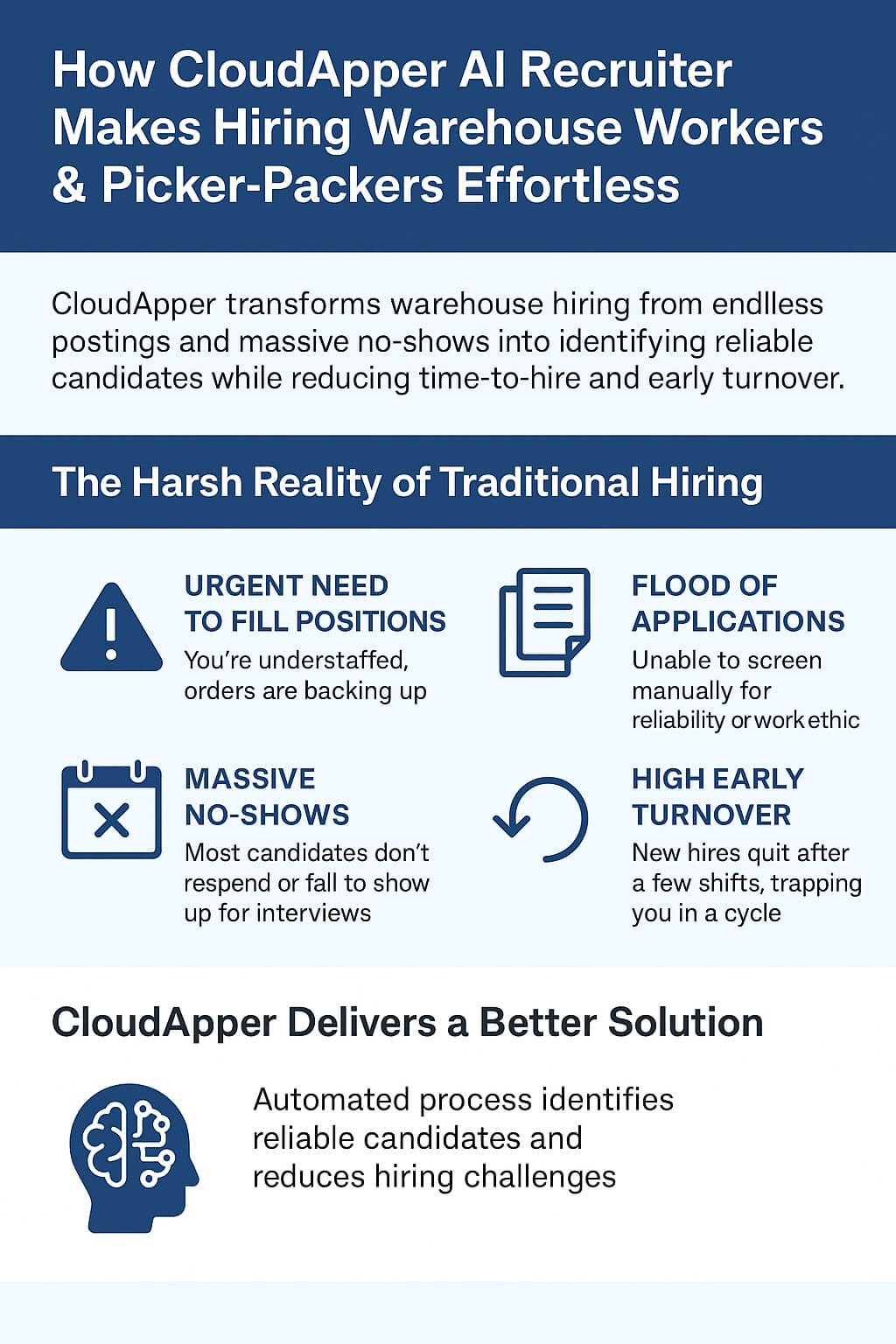

Now imagine transforming your warehouse hiring from a constant crisis—posting jobs endlessly, drowning in applications, experiencing massive no-shows, watching new hires quit within weeks—into a streamlined, automated process that identifies reliable candidates quickly while dramatically reducing time-to-hire and early turnover. That’s exactly what CloudApper AI Recruiter delivers for manufacturing and warehousing operations nationwide.

Here’s the harsh reality of traditional warehouse hiring: You need to fill positions urgently because you’re understaffed and orders are backing up. You post jobs and receive dozens or hundreds of applications, but manually screening them reveals nothing about reliability or work ethic—the factors that actually determine success. You call candidates to schedule interviews, but most don’t answer or call back. You schedule 10 interviews and 5-6 don’t show up. You hire someone who seems fine, and they work three shifts then ghost. You’re trapped in a cycle of constant recruiting, burning out your HR team and frustrating operations managers who need bodies on the floor.

CloudApper eliminates these inefficiencies while providing better predictive assessment than traditional methods.

How It Works:

The moment a candidate applies—through your careers site, Indeed, a “Text JOBS to [number]” campaign on job boards, Facebook, or even QR codes posted at truck stops and bus stations—CloudApper’s conversational AI chatbot engages them instantly via SMS or web chat. This immediate engagement is absolutely critical: industry data shows that candidates who receive instant response are 5x more likely to complete the hiring process than those who wait even 12 hours.

The AI conducts an intelligent screening conversation immediately, asking customized questions like those above—assessing warehouse experience, technology comfort, safety knowledge, physical capability understanding, reliability indicators, schedule availability, and realistic job expectations. It can present scenario-based questions: “You’re picking an order and the RF scanner shows the item in a location, but it’s not there. What do you do?”

Key Features That Transform Warehouse Hiring:

- Instant SMS Engagement & Qualification: CloudApper reaches candidates on their phones within seconds—whether they apply at 11 PM after their current job or 6 AM while job searching. This immediate response captures interest before candidates move on to other opportunities or lose momentum, dramatically reducing the 60-70% drop-off plaguing traditional processes.

- Physical Capability & Job Expectations Assessment: The AI clearly communicates job demands—lifting requirements, standing duration, shift hours, physical environment, productivity expectations—and assesses candidates’ realistic understanding and capability before you waste interview time on people who’ll quit after their first shift because “it’s harder than I thought.”

- Warehouse Technology Proficiency Screening: CloudApper asks about specific systems experience—RF scanners, WMS platforms (Manhattan, SAP EWM, Oracle, etc.), powered equipment operation, inventory management—matching candidates with relevant technical experience to your operation’s needs and reducing training time.

- Reliability & Attendance Indicator Screening: The AI asks targeted questions about attendance history, transportation reliability, childcare arrangements, shift preference consistency, and other factors that predict show-up rates. Candidates with poor reliability indicators are filtered out early, so you’re only interviewing people likely to be dependable employees.

- Schedule Availability Pre-Qualification: The AI automatically screens for availability across required shifts—nights, weekends, holidays, seasonal overtime—and only advances candidates whose schedules match your operational needs, eliminating the frustration of interviewing people who can’t work when you need them.

- Automated Interview Scheduling with Multi-Touch SMS Reminders: Once candidates pass screening, the AI offers interview slots from your calendar with automatic reminders sent via SMS at 24 hours, 4 hours, and 30 minutes before—reducing no-shows by over 60% compared to email-only communication. For warehouse roles where no-show rates often hit 50%, this alone provides massive value.

- High-Volume Hiring Support for Seasonal Ramps: When you need to hire 50, 100, or 200+ warehouse workers for peak season (retail holidays, agriculture harvest, tax season for fulfillment), CloudApper scales effortlessly—screening hundreds of applicants simultaneously 24/7 while maintaining consistent quality assessment and keeping candidates engaged through the process.

- Video Introduction Capture: CloudApper can request short video responses to key questions, allowing hiring managers to quickly assess communication skills, enthusiasm, and professionalism before investing interview time—especially valuable when hiring dozens of workers simultaneously.

Real-World Impact:

A regional 3PL (third-party logistics) company with 5 distribution centers implemented CloudApper AI Recruiter for their warehouse hiring and reduced average time-to-hire from 42 days to just 12 days. By engaging candidates via SMS immediately, pre-screening for reliability and physical capability fit, and sending automated interview reminders, they cut recruiter administrative time by 75%, reduced interview no-shows from 52% to 18%, and improved 90-day retention by 31% because better screening led to better-fit hires who understood job demands upfront.

Their VP of Operations shared: “We were in constant crisis mode—always understaffed, always recruiting, watching new hires quit within weeks. CloudApper changed everything. The AI screens out people who aren’t serious or aren’t a good fit before we waste time on them. Now we’re interviewing fewer candidates but hiring people who actually stick around. Our operations managers finally have the staffing they need to hit our fulfillment targets.”

Another e-commerce fulfillment operation used CloudApper to hire 180 seasonal warehouse workers in just four weeks during holiday ramp-up—something that previously required temporary recruiting agencies, still left them understaffed, and cost over $100,000 in agency fees. The AI handled it seamlessly while maintaining consistent screening standards across all candidates.

Ready to transform your warehouse hiring? Explore CloudApper AI Recruiter here and see how manufacturing and warehousing operations are building more reliable workforces faster than ever before.

FAQ

What are the best interview questions for warehouse picker-packers?

The top 10 focus on speed, accuracy, safety, physical stamina, teamwork, and handling pressure—exactly what predicts on-the-job success.

How can I screen warehouse workers faster?

Use AI recruiting tools like CloudApper that text candidates knockout and behavioral questions automatically inside your ATS, so only qualified applicants reach you.

What is the most important skill for a picker-packer?

Accuracy combined with consistent speed—mistakes cost money and slow shipping more than slightly slower perfect picks.

How do you test attention to detail in a warehouse interview?

Ask behavioral questions like “Tell me about a time you caught a picking error before it shipped” or give a quick mock order test.

Can AI really replace initial warehouse interviews?

Yes—for screening. AI asks the same 10 questions to every applicant instantly, scores answers, and ranks the top 10% for you to interview personally.

Stop the Cycle of Constant Warehouse Recruiting

In warehouse and manufacturing recruitment, speed and screening quality both determine success. The challenge isn’t attracting applicants—it’s identifying reliable candidates quickly, keeping them engaged through the hiring process, and reducing the massive waste of time caused by no-shows, quick quits, and poor-fit hires.

CloudApper AI Recruiter solves both problems. It engages candidates instantly when interest is highest, screens thoroughly for reliability and fit before you invest interview time, maintains engagement through automated communication that reduces no-shows by over 60%, and presents you with qualified candidates who understand job expectations and have demonstrated realistic commitment.

Your operations deserve fully-staffed warehouse teams who show up consistently and perform quality work. Your operations managers deserve to focus on running efficient operations instead of constantly covering for open positions. And your HR team deserves technology that eliminates repetitive screening tasks while delivering better hiring outcomes.

Book a demo today and see how our AI can start screening warehouse candidates within 48 hours. Let us show you how manufacturing and warehousing operations nationwide are solving the hiring crisis—one automated conversation at a time.

What’s your biggest challenge when hiring Warehouse Workers or Picker-Packers? Drop a comment below—our team would love to hear from you and share proven strategies that are working for operations facing similar hiring challenges.

You might also like to read:

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More

CloudApper AI Solutions for HR

- Works with

- and more.

Similar Posts

How cNPS Reflects Your Recruitment and Employer Brand

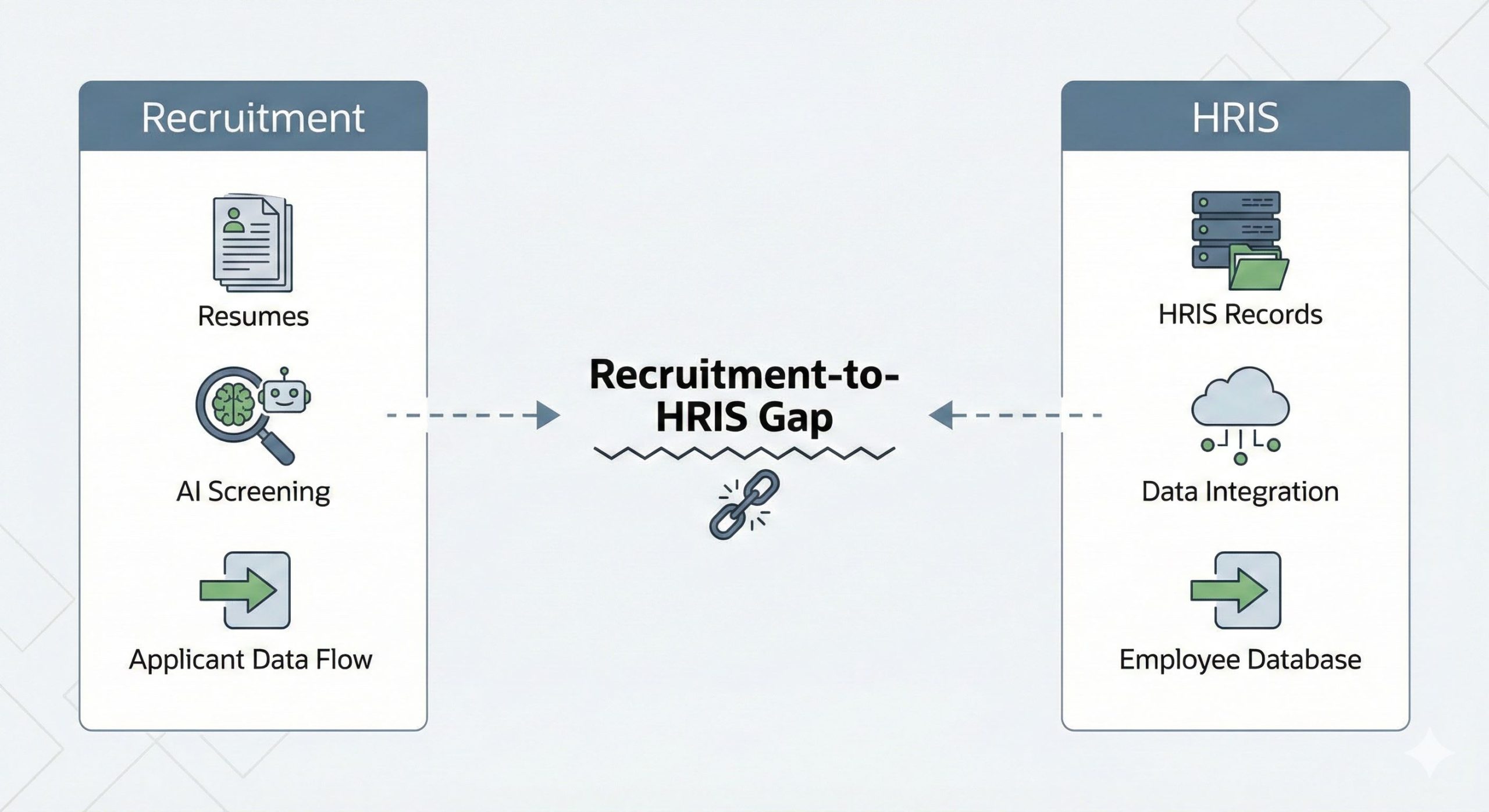

The Recruitment-to-HRIS Gap: Why Your “System of Record” Should Start…