Table of Contents

Hiring qualified forklift operators has become one of the most pressing challenges facing manufacturing and warehousing operations today. According to the American Staffing Association, warehouse and logistics companies are experiencing a staggering 90% turnover rate in some markets, with the average cost to replace a single forklift operator reaching $4,000 to $7,000 when factoring in recruiting, training, and productivity losses.

For more information on CloudApper AI Recruiter visit our page here.

The supply chain talent crisis isn’t easing up either. With e-commerce driving unprecedented demand for warehouse capacity, the competition for skilled material handling equipment operators has intensified dramatically. Recent industry data shows that warehouse job openings take an average of 45 days to fill, during which operations suffer from understaffing and existing employees face burnout from overtime demands.

But here’s where it gets even more challenging: candidate drop-off rates during the hiring process have skyrocketed. Nearly 60% of applicants abandon warehouse job applications midway through lengthy traditional screening processes. Meanwhile, the skill requirements for forklift operators have evolved beyond basic equipment operation—today’s operators need tech-savviness for warehouse management systems, attention to safety protocols, and adaptability to automated environments.

That’s exactly why forward-thinking warehouse and manufacturing HR teams are turning to CloudApper AI Recruiter, a conversational AI chatbot that screens candidates 90% faster than traditional methods, eliminates unconscious bias, and conducts simulated interviews 24/7 via text message or web chat. Instead of losing qualified candidates to slow response times or scheduling bottlenecks, our AI engages them instantly, asks the right questions, and surfaces only the most qualified operators for your final review.

In this guide, we’ll give you the exact interview questions you need to identify top-tier forklift operators, plus show you how AI handles the heavy lifting of candidate screening, engagement, and evaluation—so you can fill those critical warehouse positions faster and with better quality hires.

TL;DR

Quick Summary:

- Forklift operator hiring takes 45 days on average with high candidate drop-off

- 10 essential interview questions cover certifications, safety protocols, equipment experience, tech skills, and decision-making

- CloudApper AI Recruiter automates screening 24/7 via SMS/chat, asks customized questions, and ranks candidates instantly

- Real results: 70% faster hiring, 35% better candidate quality, 28% lower turnover

- AI eliminates bias, maintains compliance, and engages warehouse workers where they are—on their phones

Why These Questions Matter for Forklift Operators

The forklift operator role has evolved far beyond simply moving pallets from point A to point B. Today’s warehouse environments demand operators who can navigate complex inventory management systems, adapt to automated sorting technologies, and maintain rigorous safety standards in high-velocity operations. Generic “tell me about yourself” questions no longer cut it when you need to assess equipment-specific competencies, safety consciousness, problem-solving abilities, and cultural fit for fast-paced warehouse environments. The best forklift operator interview questions dig into real-world scenarios, technical knowledge, and behavioral indicators that predict success in modern material handling operations. These targeted questions help you differentiate between candidates who can merely operate equipment and those who will become reliable, safety-focused team members who contribute to operational excellence.

Top 10 Essential Forklift Operator Interview Questions (Plus How AI Recruiter Can Automate The Entire Process)

1. Describe your forklift certification and the types of equipment you’re qualified to operate.

Why ask this? This establishes baseline qualifications and helps you match candidates to your specific equipment fleet immediately.

Sample Strong Answer: “I hold a current OSHA-compliant forklift certification that I renewed six months ago, and I’ve completed additional training for sit-down counterbalance forklifts, reach trucks, and order pickers. In my last position at a high-volume distribution center, I primarily operated Crown reach trucks for narrow-aisle picking and Raymond sit-down forklifts for loading and unloading trucks. I’m also familiar with the pre-operation inspection process and maintain my training documentation through our warehouse management system.”

2. Walk me through your pre-shift forklift inspection routine.

Why ask this? Safety-conscious operators never skip inspections, and this reveals their understanding of preventive maintenance and OSHA compliance.

Sample Strong Answer: “Every shift starts with a thorough pre-operation inspection before I even start the engine. I check tire pressure and condition, look for any fluid leaks underneath, test the horn and lights, inspect the forks for cracks or damage, and verify that safety features like the overhead guard and seatbelt are functioning. I check hydraulic hoses for wear, test the brakes in an open area, and ensure the load backrest is secure. If I find any issues, I tag the equipment out of service immediately and report it to maintenance through our digital checklist system. I document every inspection because equipment safety directly impacts everyone in the warehouse.”

3. Describe a time when you identified a safety hazard in the warehouse and how you handled it.

Why ask this? This behavioral question reveals situational awareness and whether candidates take ownership of workplace safety beyond their immediate tasks.

Sample Strong Answer: “About four months ago, I noticed that a pallet rack in my zone had a damaged upright beam that was slightly bent, likely from a previous impact. Even though it wasn’t in immediate danger of collapse, I knew it could fail under full load. I immediately cordoned off the area with caution tape, reported it to my supervisor, and logged the issue in our safety reporting app. I also made sure to inform the other operators during shift changeover. Maintenance reinforced the rack that same day. I believe everyone has a responsibility to speak up about potential hazards before they become accidents—I’ve seen what happens when people stay silent, and it’s not worth the risk.”

4. How do you prioritize tasks when you’re managing multiple pick orders with tight deadlines?

Why ask this? Modern warehouses run on tight timelines, and this question assesses time management, decision-making, and pressure handling.

Sample Strong Answer: “In a fast-paced warehouse, prioritization is everything. I start by checking the warehouse management system for order deadlines and truck departure times—anything loading in the next hour takes top priority. I also batch similar picks when possible to minimize travel time and maximize efficiency. If I get conflicting priorities, I communicate immediately with the shift lead rather than guessing. I’ve learned to work smart, not just fast—rushing leads to mistakes and safety incidents. Last quarter, I maintained a 99.2% order accuracy rate even during our peak season by staying organized and communicating proactively when I needed support.”

5. What steps do you take to ensure load stability when stacking pallets or loading trucks?

Why ask this? Load stability prevents product damage, truck rejections, and serious safety incidents—this tests practical knowledge and attention to detail.

Sample Strong Answer: “Load stability starts with understanding weight distribution and the load capacity of both the forklift and the storage location. I always position heavier items on the bottom and lighter items on top, ensure pallets are properly aligned and not overhanging, and use stretch wrap or banding when necessary. When loading trucks, I work from front to back and side to side to distribute weight evenly and prevent shifting during transport. I also pay attention to the forklift’s load center and never exceed the rated capacity on the data plate. If a load feels unstable or a pallet is damaged, I don’t take chances—I rebuild it or get a supervisor’s input before moving it.”

6. How comfortable are you with using warehouse management systems or RF scanners?

Why ask this? Technology integration is now essential in modern warehouses, and tech-savvy operators are far more productive.

Sample Strong Answer: “I’m very comfortable with warehouse technology—I’ve used RF scanners daily for the past three years for picking, put-away, and cycle counting. In my current role, we use a WMS that requires scanning every item movement for inventory accuracy, and I’ve been recognized for maintaining one of the highest scan compliance rates on my shift. I’m a quick learner with new systems too—when our facility upgraded to a new WMS platform last year, I volunteered for the pilot group and helped train other operators. I understand that accurate data entry is just as important as safe equipment operation in today’s warehouses.”

7. Tell me about a time you made a mistake while operating equipment and how you handled it.

Why ask this? Everyone makes mistakes—what matters is accountability, learning, and honest self-awareness.

Sample Strong Answer: “Early in my career, I was moving quickly to meet an end-of-shift deadline and accidentally clipped a pallet rack with my forks, causing some minor damage. Nobody saw it happen, but I immediately reported it to my supervisor rather than hiding it. I took responsibility, filled out an incident report, and we reviewed the situation together. That experience taught me that no deadline is worth compromising safety or integrity. Since then, I’ve been much more deliberate about checking my clearances and slowing down in tight spaces. My supervisor actually thanked me for being honest—he said it showed character and that he’d rather know about small issues before they become big ones.”

8. How do you maintain focus and safety during long shifts or repetitive tasks?

Why ask this? Complacency is dangerous in material handling, and this reveals how candidates maintain concentration and avoid accidents.

Sample Strong Answer: “I treat every lift like it’s the first one of the day, even on hour ten of my shift. I build in small mental checkpoints—scanning my surroundings before every move, checking my mirrors, sounding my horn at intersections—so these habits become automatic even when tasks feel repetitive. I also make sure I’m taking my breaks, staying hydrated, and eating properly because fatigue is a real safety risk. If I’m feeling worn down, I communicate with my supervisor rather than pushing through when I know my focus is slipping. Over three years and thousands of hours of operation, I’ve maintained a zero-accident record because I respect the equipment and never let routine make me careless.”

9. Describe your experience working in temperature-controlled or specialized warehouse environments.

Why ask this? Many warehousing operations involve freezer storage, clean rooms, or hazardous materials that require additional skills and adaptability.

Sample Strong Answer: “I’ve spent the last 18 months working in a cold storage facility where temperatures range from -10°F in the freezer section to 35°F in the cooler areas. It requires a different mindset—equipment handles differently in extreme cold, batteries drain faster, and you need to dress appropriately while still maintaining dexterity and safety. I’ve learned to do shorter rotations in the freezer zones, keep extra batteries charged, and watch for condensation and ice buildup on equipment and floors. I’m also careful about acclimating when moving between temperature zones to avoid health issues. The experience has made me very adaptable—I know I can handle whatever specialized environment your facility requires.”

10. What questions do you have about our facility, safety culture, or growth opportunities?

Why ask this? Great candidates ask thoughtful questions that show genuine interest and long-term thinking—this also gives you a chance to sell your company.

Sample Strong Answer: “I’d like to know more about your safety incentive programs and how you recognize operators who consistently maintain high safety and quality standards. I’m also curious about the types of equipment I’d be operating here and whether there are opportunities for cross-training on different machines or even advancement into lead operator or trainer roles. Long-term, I’d love to understand how your company supports professional development—I’m interested in eventually earning my logistics certifications and growing with an organization that values continuous improvement.”

How CloudApper AI Recruiter Makes Hiring Forklift Operators Effortless

Now, here’s where hiring gets truly transformative: imagine having a tireless AI assistant that asks these exact questions (or your customized versions) to every candidate who applies, at any hour of the day or night, via text message or web chat—before you’ve even had your morning coffee.

That’s exactly what CloudApper AI Recruiter delivers for manufacturing and warehousing operations struggling to fill forklift operator positions quickly and effectively.

Here’s how our conversational AI chatbot revolutionizes the forklift operator hiring process:

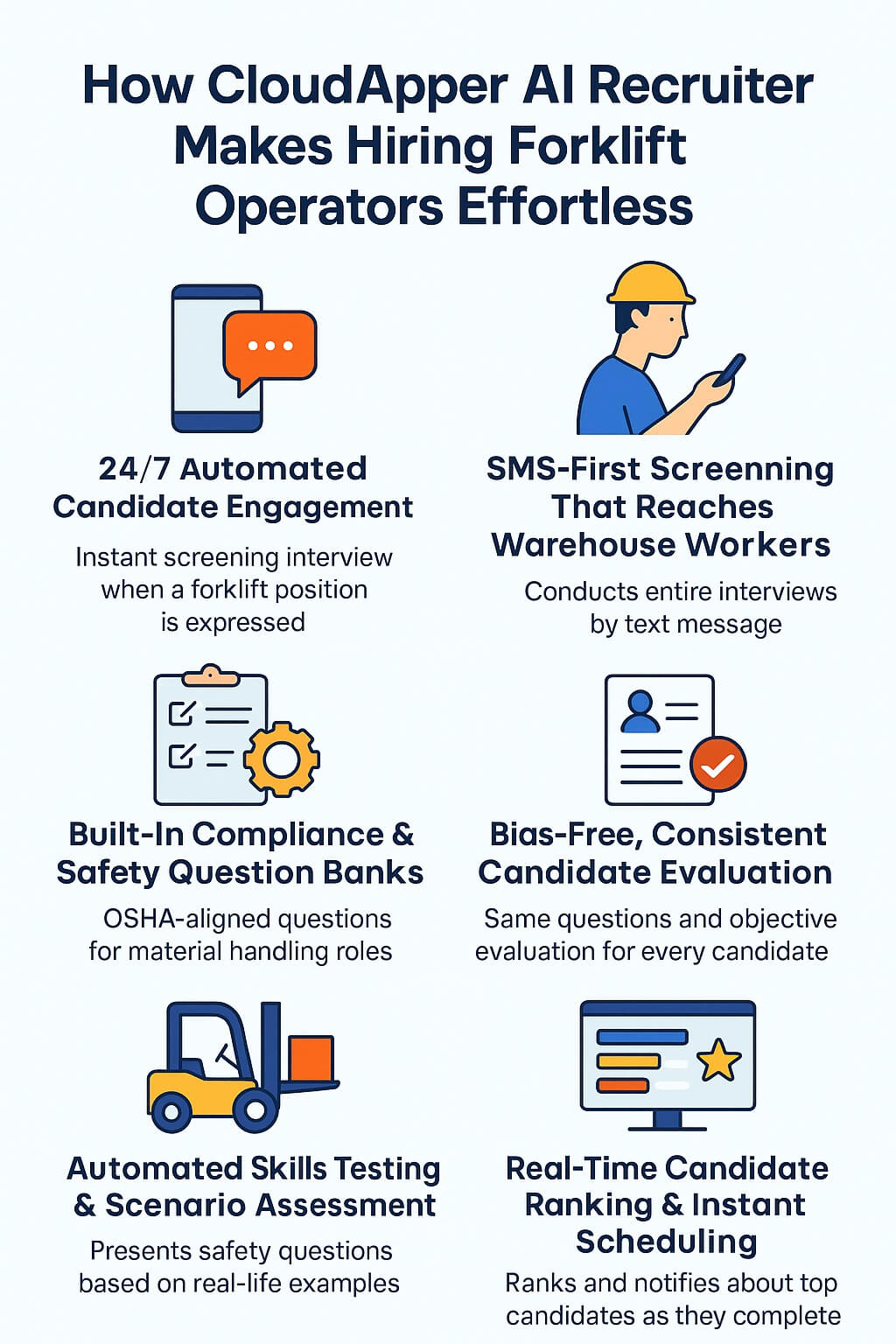

24/7 Automated Candidate Engagement

The moment someone expresses interest in your forklift position—whether through a job board, QR code at a job fair, or text-to-apply campaign—CloudApper AI Recruiter instantly engages them in a natural, conversational screening interview. No more losing qualified candidates to slow response times or phone tag. Our AI asks about their certifications, equipment experience, safety records, and availability, then scores responses based on your predetermined criteria.

SMS-First Screening That Reaches Warehouse Workers

Let’s be honest: most forklift operators aren’t sitting at computers checking email—they’re working. CloudApper AI Recruiter meets candidates where they are, conducting entire screening interviews via text message. Candidates can respond during breaks, commutes, or any convenient moment, dramatically reducing drop-off rates and improving completion rates by up to 85%.

Built-In Compliance & Safety Question Banks

Our platform comes pre-loaded with OSHA-compliant questions specific to forklift operations, material handling, and warehouse safety. You can easily customize the question flow to assess equipment-specific skills (reach trucks vs. sit-downs), shift availability, temperature tolerance for cold storage, and any other role-specific requirements. The AI even probes deeper with intelligent follow-up questions based on candidate responses.

Bias-Free, Consistent Candidate Evaluation

Every candidate gets asked the same questions in the same way, eliminating unconscious bias based on accents, appearance, or personal chemistry. CloudApper AI Recruiter evaluates responses objectively against your success criteria, ensuring that qualified candidates aren’t overlooked and that your hiring process stands up to equal employment opportunity standards.

Automated Skills Testing & Scenario Assessment

Beyond basic questions, our AI recruitment platform can present scenario-based assessments: “You notice a puddle of hydraulic fluid under your forklift during pre-shift inspection. What do you do?” The AI evaluates whether candidates demonstrate proper safety judgment, knowledge of reporting procedures, and decision-making skills that predict on-the-job success.

Real-Time Candidate Ranking & Instant Scheduling

As candidates complete their AI interviews, CloudApper automatically ranks them based on qualification match, experience level, and response quality. Your hiring managers get instant notifications about top candidates, and the AI can even schedule in-person interviews or facility tours automatically based on mutual availability—cutting your time-to-hire by an average of 70%.

Real Results from Warehouse & Manufacturing Leaders

A major third-party logistics provider in the Midwest recently implemented CloudApper AI Recruiter for their forklift operator hiring across 12 distribution centers. Within 90 days, they reduced their average time-to-hire from 42 days to just 12 days, increased candidate quality scores by 35%, and decreased new hire turnover in the critical first 90 days by 28%. Their HR team went from drowning in phone screens to focusing exclusively on facility tours and final interviews with pre-qualified, engaged candidates.

Frequently Asked Questions About Hiring Forklift Operators

Q: What are the most important forklift operator interview questions to ask?

A: The most critical questions assess OSHA certification status, pre-shift inspection knowledge, safety incident handling, load stability procedures, warehouse management system proficiency, and problem-solving under pressure. Behavioral questions about past mistakes and how candidates maintain focus during long shifts reveal character and safety consciousness better than generic questions.

Q: How can AI help with forklift operator recruitment?

A: AI recruiting tools like CloudApper AI Recruiter automate initial screening by conducting conversational interviews via SMS or chat 24/7. The AI asks customized questions about certifications, equipment experience, and safety knowledge, then scores and ranks candidates automatically. This reduces time-to-hire by 70%, eliminates bias, and prevents candidate drop-off by engaging applicants instantly on their mobile devices.

Q: What certifications should forklift operators have?

A: All forklift operators must have OSHA-compliant forklift certification specific to the equipment types they’ll operate (counterbalance, reach truck, order picker, etc.). Certifications should be current (renewed every 3 years per OSHA standards), and operators should have documentation of their training. Some facilities also require additional certifications for specialized environments like cold storage or hazardous materials handling.

Q: How long does it typically take to hire a forklift operator?

A: Traditional hiring processes take 42-45 days on average due to scheduling challenges, slow response times, and manual screening bottlenecks. However, companies using AI recruitment automation like CloudApper can reduce this to 10-14 days by instantly engaging candidates, conducting automated screenings, and surfacing only qualified operators for final interviews.

Q: What’s causing the forklift operator shortage?

A: The shortage stems from multiple factors: e-commerce driving unprecedented warehouse demand, 90% turnover rates in some markets, an aging workforce retiring, competition from other industries offering similar wages, and slow traditional hiring processes that lose candidates to faster employers. The talent pool is shrinking while demand continues to grow.

Q: How do you assess forklift operator safety awareness in interviews?

A: Ask behavioral questions about past safety incidents, pre-shift inspection routines, how they’ve identified hazards, and scenario-based questions about load stability and equipment malfunctions. Strong candidates provide specific examples, demonstrate knowledge of OSHA standards, show accountability when discussing mistakes, and emphasize that no deadline justifies compromising safety.

Q: Can CloudApper AI Recruiter screen for specialized forklift skills?

A: Yes, CloudApper AI Recruiter can be customized to assess specific equipment types (reach trucks, stand-up forklifts, clamp trucks), specialized environments (cold storage, clean rooms, hazardous materials), WMS experience, shift availability, and even present scenario-based assessments. The AI adapts follow-up questions based on candidate responses to probe deeper into relevant experience.

Q: What technology skills do modern forklift operators need?

A: Today’s forklift operators need proficiency with RF scanners, warehouse management systems (WMS), digital pre-operation inspection apps, and basic tablet/smartphone navigation. Many facilities use voice-picking systems, automated inventory tracking, and digital communication tools. Tech-savvy operators are significantly more productive and make fewer inventory errors.

The warehouse manager told us: “We were losing great operators because we couldn’t respond fast enough or schedule interviews during their limited availability. CloudApper changed everything—we’re now filling positions faster with better people, and our recruiters actually have time to build relationships instead of playing phone tag all day.”

Ready to transform how you hire forklift operators and other warehouse roles? Discover how CloudApper AI Recruiter can reduce your time-to-hire, eliminate screening bottlenecks, and help you build a stronger warehouse team.

Stop Losing Warehouse Talent to Slow Hiring Processes

The competition for qualified forklift operators isn’t slowing down—but your hiring process can speed up dramatically. With CloudApper AI Recruiter, you’ll engage candidates instantly, screen efficiently, and identify top talent faster than ever before, all while maintaining consistency and compliance throughout your hiring process.

These 10 interview questions give you the foundation for identifying skilled, safety-conscious forklift operators. But asking them manually through endless phone screens is exactly what’s keeping your positions open for weeks or months. Let AI handle the initial screening conversations so your team can focus on welcoming qualified operators into your facility and getting them productive faster.

Book a demo of CloudApper AI Recruiter today and see how conversational AI can transform your warehouse and manufacturing hiring—we’ll show you exactly how to customize the platform for your forklift operator hiring needs and get you up and running in days, not months.

What’s your biggest challenge in hiring forklift operators right now? Drop a comment below and let’s discuss how AI recruiting can solve your specific pain points.

You might also like to read:

10 Crucial Interview Questions for Quality Control Inspectors in Manufacturing & Warehousing with AI Recruiter Automation10 Crucial Interview Questions for Production Line Workers & Assembly Technicians in Manufacturing with AI Recruiter Automation

10 Crucial Interview Questions for Warehouse Workers & Picker-Packers (+ AI Recruiter Automation)

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More