Manufacturing faces severe staffing shortages with high hiring costs and long time-to-fill periods. These 10 targeted interview questions assess experience, quality awareness, safety, teamwork, and reliability in production line roles. CloudApper AI Recruiter automates conversational screening via text, engaging candidates 24/7 to deliver qualified applicants faster and bias-free.

Table of Contents

Manufacturing facilities across North America are facing an unprecedented crisis in frontline staffing. According to the National Association of Manufacturers, 77% of manufacturers report moderate to severe difficulty attracting and retaining production workers, with the average cost to hire a single production line worker now exceeding $4,500 when factoring in recruiting expenses, training, and lost productivity during the hiring gap.

For more information on CloudApper AI Recruiter visit our page here.

The numbers paint an even grimmer picture: the manufacturing sector currently has over 600,000 unfilled positions, and industry analysts project this gap will grow to 2.1 million by 2030 as the workforce ages out. Meanwhile, the average time-to-fill for production line worker and assembly technician positions has stretched to 52 days—nearly two months during which your production lines run understaffed, overtime costs escalate, and quality issues multiply.

But the challenge isn’t just finding candidates; it’s engaging them fast enough. Recent data shows that 58% of manufacturing job applicants drop out of the hiring process before completing initial screening, primarily due to slow response times and cumbersome application procedures. With younger workers accustomed to instant digital interactions, the traditional “apply and wait” model simply doesn’t work anymore.

The role itself has evolved dramatically too. Today’s production line workers and assembly technicians need more than strong backs and willing hands—they need technical aptitude for increasingly automated equipment, comfort with digital work instructions and quality management systems, problem-solving skills for continuous improvement initiatives, and adaptability as manufacturing embraces Industry 4.0 technologies.

That’s exactly why forward-thinking manufacturing HR leaders are turning to CloudApper AI Recruiter, a conversational AI chatbot that screens candidates 90% faster than traditional methods, eliminates unconscious bias, and conducts simulated interviews 24/7 via text message or web chat. Instead of losing qualified production workers to competitors with faster processes, our AI engages them within minutes, asks the right role-specific questions, and surfaces only the most qualified candidates for your floor supervisors to meet.

In this guide, we’ll give you the exact interview questions you need to identify reliable, skilled production line workers and assembly technicians—plus show you how AI handles the heavy lifting of candidate engagement, screening, and evaluation so you can keep your production lines fully staffed.

Why These Questions Matter for Production Line Workers & Assembly Technicians

The production line worker role has transformed from purely manual labor to a hybrid position requiring technical competence, quality consciousness, and continuous improvement mindset. Generic questions like “Why do you want to work here?” or “What are your strengths?” fail to assess the specific competencies that predict success in modern manufacturing environments. Today’s assembly technicians must navigate digital work instructions, troubleshoot semi-automated equipment, maintain precise quality standards, document issues in real-time systems, and collaborate across shifts to solve production bottlenecks. The best production line worker interview questions dig into hands-on experience, problem-solving approaches, safety awareness, attention to detail, and cultural fit for fast-paced, team-oriented manufacturing environments. These targeted questions help you identify candidates who won’t just show up—they’ll contribute to operational excellence, quality improvements, and long-term retention on your production floor.

Top 10 Essential Production Line Worker & Assembly Technician Interview Questions (Plus How AI Recruiter Can Automate The Entire Hiring Process)

1. Describe your experience working on production lines or in assembly environments. What types of products or components have you worked with?

Why ask this?

This establishes baseline manufacturing experience and helps you assess whether their background aligns with your specific production processes and complexity level.

Sample Strong Answer: “I’ve spent the last three years working on an automotive parts production line where we manufactured brake assemblies. My station involved torque-specific fastening using digital torque wrenches, visual inspection against quality specs displayed on a monitor, and documenting any defects in our tablet-based quality system. Before that, I worked in consumer electronics assembly doing PCB component placement and soldering. I’m comfortable with both high-volume repetitive work and the precision required for complex assemblies. I’ve worked with hand tools, power tools, and semi-automated equipment, and I understand how important consistency and attention to detail are when you’re making thousands of the same part every day.”

2. Walk me through how you would identify and respond to a quality issue you noticed during assembly.

Why ask this?

Quality consciousness and problem-solving initiative are critical—this reveals whether candidates take ownership or just pass problems along.

Sample Strong Answer: “First, I’d stop and not continue assembling defective parts—that would just multiply the problem. I’d immediately notify my team lead or quality technician and show them exactly what I’m seeing. If we have an andon system, I’d pull the cord to signal the issue. I’d also check the last few units I completed to see if the problem started earlier. Once we identify the root cause—whether it’s a bad batch of components, a tool that’s out of calibration, or an unclear work instruction—I’d follow the corrective action process. I learned early in my career that catching one defect at my station is way better than having a hundred defective units reach the customer. Quality is everyone’s responsibility, not just QC’s job.”

3. Tell me about a time when you had to meet a tight production deadline or quota. How did you handle the pressure?

Why ask this?

Manufacturing operates on deadlines and throughput targets—this assesses stress management, work ethic, and reliability under pressure.

Sample Strong Answer: “Last quarter, we had a major customer order that required us to increase our line speed by 20% for two weeks straight. Instead of panicking, I focused on working smarter—I organized my tools and parts better so I wasn’t wasting motion, I coordinated with the upstream station to get a smoother flow, and I volunteered for overtime when needed. I also made sure I was taking my breaks and staying hydrated because I knew burnout would hurt quality. Our team not only hit the deadline but maintained our 99.1% quality rate. The key was staying focused on my process, supporting my teammates when they fell behind, and not letting the pressure make me rush and make mistakes.”

4. How do you maintain focus and accuracy during repetitive tasks over an 8-10 hour shift?

Why ask this?

Repetitive work can lead to mental fatigue and mistakes—strong candidates have strategies to maintain performance throughout their shift.

Sample Strong Answer: “I treat every unit like it’s the first one, even if I’m doing the same assembly 500 times a day. I build small mental checkpoints into my process—checking my torque setting before each fastener, visually inspecting orientation before placement, scanning the barcode to confirm the right part. These little rituals keep me engaged. I also stay physically comfortable by using good ergonomics and adjusting my station setup. During breaks, I get away from my station completely to reset mentally. I’ve learned that maintaining quality for ten hours is actually easier than letting your standards slip because then you’re stressed about mistakes and rework. Consistency is a skill you develop, not just something you’re born with.”

5. Describe your experience with manufacturing equipment, tools, or technology. Are you comfortable learning new systems?

Why ask this?

Technical adaptability is increasingly important as manufacturing automates and digitizes—this reveals both current capabilities and learning aptitude.

Sample Strong Answer: “I’m proficient with standard hand and power tools—torque wrenches, impact drivers, drills, grinders—and I understand proper tool maintenance and calibration. I’ve operated digital calipers and micrometers for precision measurement, and I’m comfortable with barcode scanners and tablets for work instructions and quality documentation. At my last facility, we transitioned from paper travelers to a digital manufacturing execution system, and I was selected to be a super-user to help train others. I’m definitely comfortable learning new technology—I actually prefer it because digital systems usually make the job easier and more accurate. I understand that manufacturing is constantly evolving, and I see learning new equipment and systems as part of staying valuable in this industry.”

6. What does workplace safety mean to you, and how do you practice it daily?

Why ask this?

Safety culture starts with individual commitment—this question reveals whether candidates genuinely prioritize safety or just give lip service to it.

Sample Strong Answer: “Safety means going home in the same condition I arrived, every single day, and making sure my coworkers do too. Practically, that means always wearing required PPE even when it’s uncomfortable, following lockout-tagout procedures without shortcuts, keeping my work area clear of trip hazards, and speaking up when I see unsafe conditions or behaviors. I do safety checks before starting any new task—making sure guards are in place, emergency stops work, and I understand the hazards. I’ve also learned to watch my ergonomics because repetitive strain injuries are just as real as acute accidents. Last year, I noticed a coworker developing bad lifting habits and I talked to him about it privately—two weeks later he thanked me because his back pain had gone away. Safety isn’t just rules, it’s a mindset.”

7. How do you handle working as part of a production team, especially when different shifts or departments depend on your work?

Why ask this?

Manufacturing is inherently collaborative, and one person’s problems cascade to everyone downstream—this assesses teamwork and accountability.

Sample Strong Answer: “I understand that in manufacturing, we’re all links in a chain—if I mess up or fall behind, it affects everyone downstream and the next shift. That’s why I focus on consistency and clear communication. If I encounter a problem that will impact my output, I notify the next station and my supervisor immediately so they can adjust. During shift changeovers, I give a thorough handoff—where we stand on the production schedule, any quality issues I noticed, any equipment that’s acting up. I also help teammates who are struggling rather than just watching them fall behind, because their success is my success. The best production teams I’ve been on weren’t the ones with the most talented individuals—they were the ones where everyone looked out for each other and held each other accountable to high standards.”

8. Tell me about a time you suggested an improvement to a work process. What was the result?

Why ask this?

Continuous improvement depends on frontline worker observations—this identifies candidates who actively think about making things better, not just executing tasks.

Sample Strong Answer: “At my previous job, I noticed we were wasting a lot of time walking back and forth to get hardware from bins that were 30 feet away from our assembly stations. I sketched out a simple idea for a mobile cart that would hold the most common fasteners right at the line. I showed it to my supervisor during our weekly team meeting, and he loved it. Maintenance built three carts based on my design, and we estimated it saved each operator about 45 minutes per shift in walking time—that’s huge when multiplied across 15 operators. I got recognized in the plant newsletter and received a continuous improvement award. That experience taught me that companies value workers who think, not just workers who follow instructions. I’m always looking for small ways to make processes safer, faster, or more ergonomic.”

9. How do you handle situations where you’re given unclear work instructions or notice a potential mistake in the documentation?

Why ask this?

Work instructions aren’t always perfect, and this reveals problem-solving initiative versus blindly following potentially incorrect directions.

Sample Strong Answer: “I never just guess or assume when instructions aren’t clear—that’s how you make expensive mistakes. If I receive unclear work instructions or notice something that doesn’t seem right, I stop and ask my team lead or supervisor for clarification before proceeding. I’ll explain specifically what I’m uncertain about and why I think there might be an issue. I’ve caught several documentation errors this way—wrong torque specs, incorrect part numbers, missing assembly steps—and each time, my supervisor thanked me for catching it before it became a quality problem. I’d rather ask what seems like a basic question than assemble a thousand units incorrectly. Good manufacturing depends on following processes, but it also depends on people who think critically and speak up when something doesn’t make sense.”

10. What’s your approach to attendance and reliability? How do you handle situations when you can’t make it to work?

Why ask this?

Absenteeism cripples production schedules—direct questions about attendance help identify candidates with strong work ethic and accountability.

Sample Strong Answer: “I take attendance very seriously because I know an empty station means someone else has to cover my work or the whole line slows down. In three years at my current job, I’ve only missed four days—two for a planned surgery and two for a family emergency. I understand that in manufacturing, calling off impacts the whole team. If I absolutely can’t make it in, I call my supervisor as soon as I know, not five minutes before my shift starts, so they have time to find coverage. I also make myself available to cover shifts when others need time off because I know that flexibility goes both ways. I view showing up on time, every day, ready to work as the most basic expectation of this job—everything else builds on that foundation. Manufacturing runs on reliability, and I pride myself on being someone my team can count on.”

How CloudApper AI Recruiter Makes Hiring Production Line Workers & Assembly Technicians Effortless

Now here’s where manufacturing hiring gets truly revolutionary: imagine having an AI recruiting assistant that engages every production worker candidate instantly—day or night, weekend or holiday—asks these exact interview questions (or your customized versions) via text message, evaluates their responses against your success criteria, and surfaces only the most qualified candidates for your floor supervisors to meet.

That’s precisely what CloudApper AI Recruiter delivers for manufacturing facilities struggling to fill frontline production positions quickly and cost-effectively.

Here’s how our conversational AI chatbot transforms production line worker and assembly technician hiring:

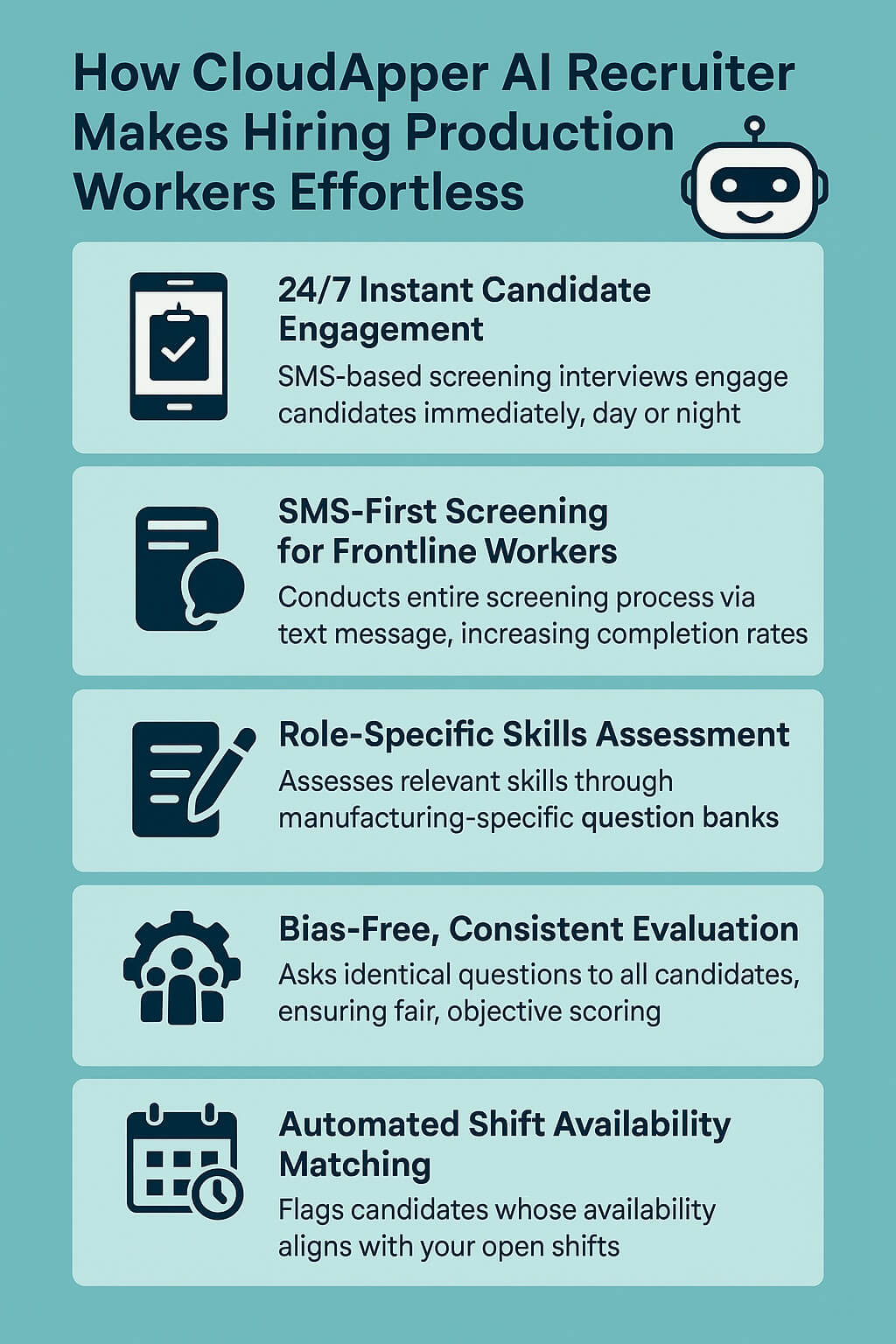

24/7 Instant Candidate Engagement

The moment someone expresses interest in your production positions—whether through a job board, QR code posted at your facility entrance, text-to-apply campaign, or employee referral—CloudApper AI Recruiter engages them immediately in a natural, conversational screening interview. No more losing qualified production workers to competitors who respond faster. Our AI asks about their manufacturing experience, technical skills, shift availability, safety mindset, and reliability, then automatically scores and ranks responses based on your predetermined criteria.

SMS-First Screening for Frontline Workers

Let’s be honest: most production line workers aren’t sitting at computers checking email—they’re working shifts, juggling family responsibilities, or job-hunting during breaks. CloudApper AI Recruiter meets candidates where they are by conducting entire screening interviews via text message. Candidates can respond during their commute, lunch break, or any convenient moment, which dramatically increases completion rates (89% average) and prevents the candidate drop-off that kills traditional application processes.

Role-Specific Skills Assessment

Our platform comes pre-loaded with manufacturing-specific question banks covering hand tool proficiency, quality inspection experience, safety protocols, blueprint reading, measurement tools, and technical aptitude. You can easily customize questions to assess specific skills like torque wrench operation, SMT soldering, forklift certification, or lean manufacturing knowledge. The AI even presents scenario-based questions—”You notice your upstream station is passing defective parts. What do you do?”—and evaluates responses for problem-solving ability and quality consciousness.

Bias-Free, Consistent Evaluation

Every candidate gets asked identical questions in the same sequence, eliminating unconscious bias based on communication style, accents, or personal rapport during phone screens. CloudApper AI Recruiter evaluates responses objectively against job-relevant criteria like experience level, technical knowledge, safety awareness, and reliability indicators. This creates fairer hiring outcomes while strengthening your compliance with equal employment opportunity standards.

Automated Shift Availability Matching

One of the biggest challenges in manufacturing hiring is matching candidate availability to your shift needs. Our AI automatically asks about preferred shifts, weekend availability, overtime willingness, and start date flexibility, then flags candidates whose availability aligns with your open positions. No more getting to final interviews only to discover the candidate can’t work nights or weekends when that’s exactly what you need.

Real-Time Candidate Ranking & Supervisor Alerts

As candidates complete their AI screening interviews, CloudApper automatically ranks them based on qualification match, experience level, skills assessment scores, and response quality. Your hiring managers receive instant mobile alerts about top candidates, complete with conversation transcripts and recommendation scores. The AI can even automatically schedule facility tours or supervisor interviews based on mutual availability—cutting your average time-to-hire by 68%.

Real Results from Manufacturing Leaders

A mid-sized automotive parts manufacturer in Michigan recently implemented CloudApper AI Recruiter across their three production facilities. Within 90 days, they reduced their average time-to-hire for production line workers from 52 days to just 17 days, increased their candidate quality scores by 41%, and decreased 90-day turnover among new hires by 34%. Their HR team went from drowning in phone screens and scheduling coordination to focusing exclusively on facility tours and final interviews with pre-qualified, engaged candidates.

Their HR Director told us: “We were losing great production workers because we couldn’t respond to applications fast enough or schedule interviews around their current work schedules. CloudApper changed everything—we’re now filling production positions three times faster with better people, and our recruiters actually have time to build relationships with candidates instead of playing phone tag all week.”

Ready to transform how you hire production line workers and assembly technicians? Discover how CloudApper AI Recruiter can eliminate your frontline hiring bottlenecks, reduce time-to-hire, and help you build a stronger, more reliable production workforce.

FAQ

Why are targeted interview questions important for hiring production line workers?

Generic questions miss critical skills like technical aptitude, quality control, safety mindset, and adaptability needed in modern manufacturing environments.

What skills should production line workers and assembly technicians have today?

Beyond manual labor, they need comfort with automated equipment, digital instructions, problem-solving, attention to detail, and teamwork for Industry 4.0 processes.

How does CloudApper AI Recruiter help with manufacturing hiring challenges?

It engages candidates instantly via SMS, asks customized questions, scores responses objectively, matches shift availability, and ranks applicants—cutting time-to-hire and dropout rates.

What are common reasons candidates drop out of manufacturing hiring processes?

Slow response times, cumbersome applications, and lack of mobile-friendly options cause high dropout, especially among frontline workers used to instant communication.

How can AI improve bias and consistency in production worker screening?

AI asks identical questions to every candidate, evaluates responses based on job criteria, and removes subjective factors like communication style or rapport.

What results have manufacturers seen using CloudApper AI Recruiter?

One company reduced time-to-hire from 52 to 17 days, improved candidate quality by 41%, and lowered 90-day turnover by 34%.

Stop Losing Production Talent to Slow Hiring Processes

The competition for qualified production line workers and assembly technicians isn’t slowing down—but your hiring process can speed up dramatically. With CloudApper AI Recruiter, you’ll engage candidates instantly, screen efficiently around their schedules, and identify reliable, skilled workers faster than ever before, all while maintaining consistency and compliance throughout your hiring process.

These 10 interview questions give you the foundation for identifying quality production workers who will show up, work safely, contribute to continuous improvement, and stay with your organization long-term. But asking them manually through endless phone screens is exactly what’s keeping your production positions open for weeks or months while your existing workforce burns out on overtime.

Let AI handle the initial screening conversations so your floor supervisors can focus on meeting qualified candidates face-to-face and getting them onboarded quickly.

Book a demo of CloudApper AI Recruiter today and see how conversational AI can transform your manufacturing hiring—we’ll show you exactly how to customize the platform for your production worker hiring needs and get you up and running in days, not months.

What’s your biggest challenge in hiring production line workers or assembly technicians right now? Drop a comment below and let’s discuss how AI recruiting can solve your specific frontline staffing pain points.

You might also like to read:

10 Crucial Interview Questions for Warehouse Workers & Picker-Packers (+ AI Recruiter Automation)

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More

CloudApper AI Solutions for HR

- Works with

- and more.

Similar Posts

How cNPS Reflects Your Recruitment and Employer Brand

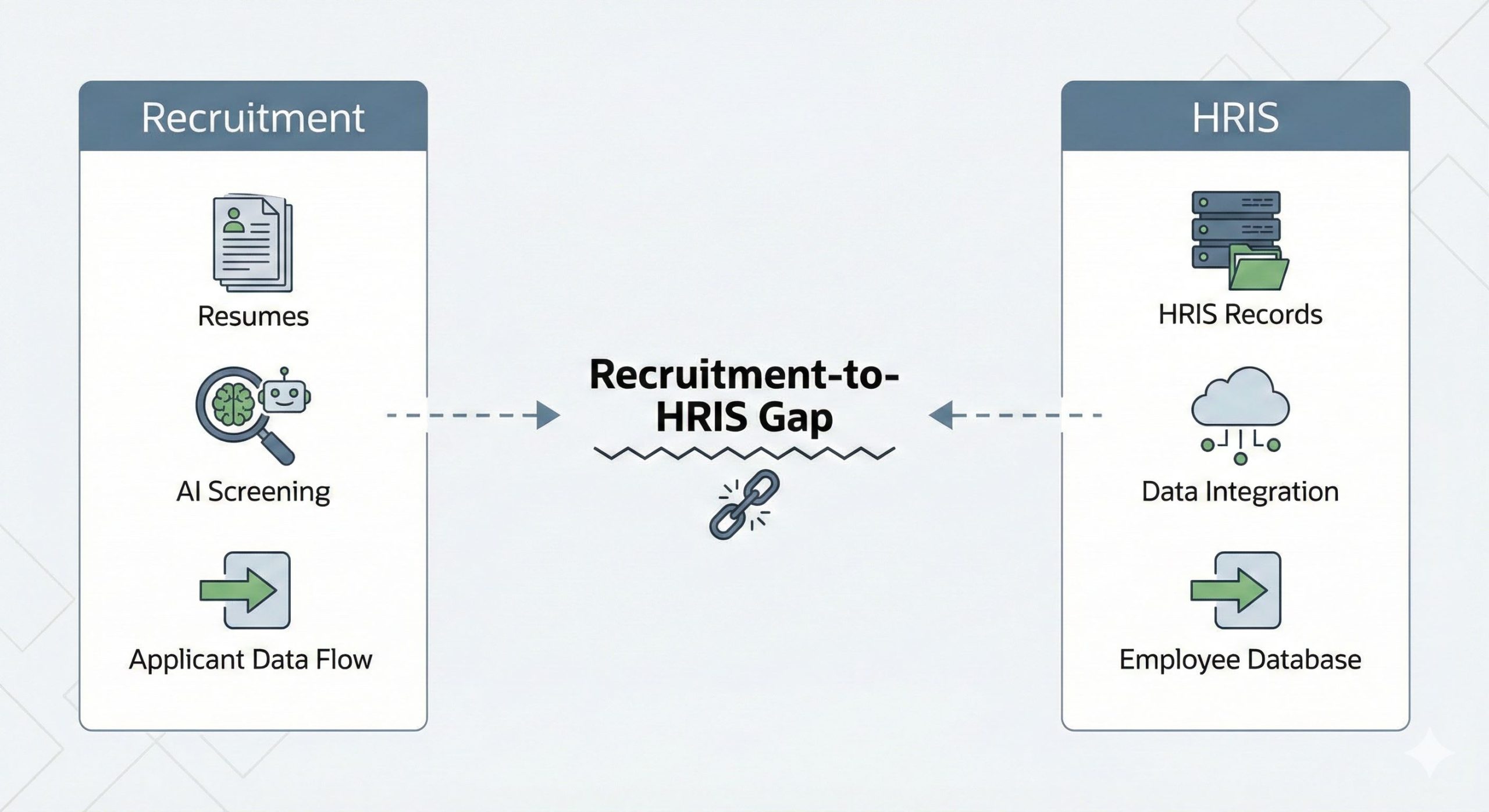

The Recruitment-to-HRIS Gap: Why Your “System of Record” Should Start…