Manufacturing faces severe machine operator shortages with high hiring costs and 60+ day cycles. These 10 targeted questions assess technical experience, troubleshooting, quality control, and safety mindset. CloudApper AI Recruiter automates instant, text-based screening to engage candidates 24/7, rank qualifications, and deliver pre-vetted operators faster.

Table of Contents

Manufacturing facilities are experiencing a critical machine operator shortage that’s directly impacting production capacity and bottom-line profitability. According to the Manufacturing Institute, 80% of manufacturers report difficulty finding qualified machine operators, with specialized CNC and automated equipment operators being particularly hard to source. The average cost to hire a skilled machine operator now exceeds $6,200 when factoring in recruiting expenses, training investments, and productivity losses during the 60+ day average hiring cycle.

For more information on CloudApper AI Recruiter visit our page here.

The skills gap compounds the problem. As manufacturing embraces Industry 4.0 technologies, today’s machine operators need capabilities far beyond what was required even five years ago. They must understand programmable logic controllers (PLCs), interpret digital work instructions, troubleshoot automated systems, and work collaboratively with robotics and AI-assisted equipment. Yet traditional recruiting methods still screen for yesterday’s skills while missing the technical aptitudes that predict success in modern manufacturing environments.

Candidate experience issues make matters worse. Research shows that 62% of manufacturing job applicants abandon the hiring process before completing initial screening, primarily because of slow response times and cumbersome application procedures. When a skilled CNC operator applies to five companies simultaneously, the one that responds within minutes—not days—wins the talent.

The financial stakes are enormous. Every week a critical machine sits idle or runs at reduced capacity due to operator shortages, costs manufacturers tens of thousands in lost production, overtime premiums for existing staff, and delayed customer commitments. Meanwhile, rushed hiring decisions to fill gaps quickly result in quality issues, safety incidents, and costly turnover when poor-fit operators don’t work out.

That’s exactly why innovative manufacturing HR teams are deploying CloudApper AI Recruiter, a conversational AI chatbot that screens machine operator candidates 90% faster than traditional methods, eliminates unconscious bias, and conducts sophisticated technical interviews 24/7 via text message or web chat. Instead of losing qualified operators to competitors with faster processes, our AI engages them within minutes, asks role-specific technical questions, assesses problem-solving capabilities, and surfaces only the most qualified candidates for your production managers to meet.

In this comprehensive guide, we’ll give you the exact interview questions you need to identify skilled, reliable machine operators who can handle your equipment and contribute to operational excellence—plus show you how AI handles the heavy lifting of candidate outreach, engagement, screening, and evaluation so you can keep your machines running at full capacity.

TL;DR

Machine operators are in short supply amid Industry 4.0 demands for technical skills. Use these 10 key interview questions to evaluate setup proficiency, troubleshooting, quality, and maintenance. CloudApper AI Recruiter transforms hiring with 24/7 SMS screening, bias-free technical assessments, shift matching, and real-time ranking—cutting time-to-hire by 72%.

Why These Questions Matter for Machine Operators

The machine operator role has evolved from button-pushing and dial-watching to sophisticated technical work requiring mechanical aptitude, digital literacy, quality consciousness, and continuous improvement mindset. Generic interview questions like “Why do you want this job?” or “Where do you see yourself in five years?” fail to assess the specific competencies that determine whether an operator will excel or struggle on your production floor. Today’s machine operators must understand equipment setup and changeovers, interpret G-code or control parameters, perform preventive maintenance, troubleshoot malfunctions using diagnostic tools, maintain tight tolerances, document production data digitally, and collaborate across shifts to optimize output. The best machine operator interview questions dig into hands-on technical experience, problem-solving approaches under pressure, quality and safety mindfulness, mechanical reasoning, and cultural fit for precision-focused manufacturing environments. These targeted questions help you differentiate between candidates who can merely keep machines running and those who will maximize uptime, minimize scrap, mentor newer operators, and drive continuous improvement initiatives that strengthen your entire operation.

Top 10 Essential Machine Operator Interview Questions (Plus How AI Recruiter Can Automate The Entire Hiring Process)

1. Describe your experience operating manufacturing equipment. What types of machines have you run, and what were your primary responsibilities?

Why ask this? This establishes baseline technical experience and helps you assess whether their background aligns with your specific equipment types, complexity levels, and production requirements.

Sample Strong Answer: “I’ve been operating CNC milling machines for the past four years, primarily Haas VF-series mills producing precision aerospace components. My responsibilities included loading programs from the server, performing tool offsets and work coordinate setups, conducting first-article inspections with CMM verification, monitoring cycle times and making feed rate adjustments, performing tool changes and offset adjustments as tools wear, and documenting all measurements in our quality management system. Before that, I operated hydraulic injection molding presses where I managed material drying, mold temperature controls, and cycle optimization. I’m comfortable reading blueprints, using precision measurement tools, and understanding how machine parameters affect part quality. I’ve also been trained on lockout-tagout procedures and basic preventive maintenance tasks like lubrication and coolant management.”

2. Walk me through your machine setup process when starting a new production run or after a changeover.

Why ask this? Setup proficiency directly impacts efficiency and first-pass quality—this reveals technical competence, attention to detail, and whether they follow proper procedures.

Sample Strong Answer: “Setup starts with thoroughly reviewing the work order, blueprint, and any special instructions to understand the part requirements and tolerances. I verify I have the correct program loaded, the right tools in the magazine with proper offsets entered, and all required fixtures and workholding devices. I set up my measuring instruments and calibrate them if needed. Then I run a dry cycle without material to verify tool paths and check for any interference issues. Once that’s good, I run a first piece, inspect all critical dimensions, and compare against the blueprint specs. If everything’s within tolerance, I get QC approval before running production. I also make sure my documentation is ready—lot numbers, material certs, inspection sheets—because good record-keeping is just as important as running the machine correctly. A careful setup prevents hours of rework later.”

3. Describe a time when your machine experienced an unexpected malfunction or breakdown. How did you troubleshoot and resolve it?

Why ask this? Downtime costs thousands per hour—strong operators diagnose problems methodically rather than panicking or blindly calling maintenance for every issue.

Sample Strong Answer: “About six months ago, my CNC lathe started producing parts that were consistently 0.003 inches oversized on a critical diameter, even though nothing had changed in the program. Instead of continuing to make bad parts, I stopped production immediately. I first checked the obvious things—verified my tool offsets hadn’t shifted, checked that the workpiece was secure in the chuck, made sure coolant flow was adequate. Everything looked good. Then I ran a test cut and paid close attention to the actual machining—I noticed the tool was chattering slightly. I checked tool wear with a magnifier and found the insert had a small chip on the cutting edge. I indexed to a fresh cutting edge, re-set my offsets, ran another test piece, and everything was back in spec. The whole troubleshooting process took about 20 minutes, and I documented it in our maintenance log so the pattern would be visible if it happened again. My supervisor appreciated that I diagnosed and fixed it myself rather than losing two hours waiting for maintenance on something straightforward.”

4. How do you ensure consistent part quality when running high-volume production?

Why ask this? Quality consistency separates excellent operators from average ones—this assesses their quality consciousness, measurement discipline, and process control understanding.

Sample Strong Answer: “Consistent quality starts with a stable process. Once I’ve dialed in my setup, I don’t make unnecessary adjustments—I let the process run and monitor it carefully. I perform in-process inspections at regular intervals using a documented frequency, not just when I feel like it. For critical dimensions, I use SPC charting to track trends—if I see measurements drifting toward a tolerance limit, I make small corrections before parts go out of spec. I also watch for warning signs during production: changes in chip formation, unusual sounds, vibration, surface finish variations. These often indicate something’s changing before it shows up in measurements. I keep detailed records of all my measurements and any adjustments I make because that data helps identify patterns and root causes when issues do occur. In my last role, I maintained a 99.4% first-pass yield over an 18-month period on a demanding aerospace contract by staying vigilant and never assuming everything’s fine just because it was fine an hour ago.”

5. What’s your approach to preventive maintenance and daily machine care?

Why ask this? Operators who maintain their equipment have dramatically better uptime and produce higher quality—this reveals ownership mentality versus “not my job” attitudes.

Sample Strong Answer: “I treat the machines I operate like they’re mine because I know my productivity depends on their reliability. Every shift starts with my pre-operation checklist: checking oil and hydraulic fluid levels, inspecting belts and hoses for wear, verifying that all guards and safety interlocks are functioning, clearing any chips or debris from critical areas, and checking that the coolant is clean and at the right level. Throughout the shift, I monitor for any unusual noises, vibrations, or temperature changes that might indicate developing problems. At shift end, I clean the machine thoroughly—chips and coolant residue cause accelerated wear and corrosion. I also perform the scheduled PM tasks assigned to operators, like greasing slide ways and replacing worn tooling before it fails. If I notice anything concerning, I document it and notify maintenance rather than waiting for it to become a breakdown. In four years of operating expensive CNC equipment, I’ve never had a major breakdown on my watch because I catch and report small issues before they become big problems.”

6. How do you handle situations where production demands conflict with quality or safety requirements?

Why ask this? This reveals integrity, judgment, and whether candidates will take shortcuts under pressure—critical for safety culture and quality standards.

Sample Strong Answer: “Quality and safety are never negotiable, regardless of production pressure. If my supervisor asks me to run faster than the proven process parameters allow, I’ll respectfully explain the risks—increased tool wear, potential quality issues, safety concerns—and suggest alternatives like adding overtime or bringing in temporary help. I’ve been in situations where we were behind schedule and the pressure was intense, but I’ve seen what happens when operators take shortcuts: scrapped parts, damaged equipment, injuries, customer complaints. None of those outcomes help meet production goals. Last year, we had a rush order and my manager asked if I could skip some inspection steps to save time. I explained that those inspections were in place because this customer had zero tolerance for defects, and one bad shipment would cost us the account. He appreciated my honesty and we found another way to expedite the order. I’m absolutely committed to meeting production goals, but I do it by working smart and efficiently within our quality and safety standards, not by compromising them.”

7. Describe your experience reading technical drawings, work instructions, or machine programs.

Why ask this? Technical literacy is non-negotiable for modern machine operators—this assesses their ability to interpret the information that drives quality production.

Sample Strong Answer: “I’m very comfortable reading and interpreting technical drawings. I understand GD&T symbols and what they mean for machining—profile tolerances, positional callouts, surface finish requirements, datum references. I can look at a blueprint and visualize how the part should be machined, which surfaces need to be held to tight tolerances, and where potential issues might arise. I’ve worked with both 2D drawings and 3D model-based definitions. For CNC work, I can read through G-code programs to understand the machining sequence, identify tool changes, spot potential problems like rapid moves that might be too aggressive. I don’t just blindly run programs—I review them first to make sure they make sense. I’m also experienced with digital work instructions on tablets where you can zoom in on specific features and access related documents. If something in a drawing or program doesn’t make sense or seems contradictory, I always ask for clarification before machining rather than guessing. Technical literacy is fundamental to producing quality parts efficiently.”

8. Tell me about your experience with measurement tools and quality inspection procedures.

Why ask this? Operators must verify their own work accurately—this assesses hands-on metrology skills and quality mindset beyond just running machines.

Sample Strong Answer: “I’m proficient with a full range of measurement tools. For everyday work, I use micrometers, calipers, height gauges, and pin gauges regularly. I understand proper measurement technique—cleaning parts and instruments, using appropriate measuring force, taking multiple readings to ensure consistency. For more complex inspection, I’ve been trained on CMM operation for first-article and in-process verification. I can also use optical comparators for profile inspection and thread gauges for threaded features. I know how to read inspection procedures and sampling plans, and I understand the difference between critical, major, and minor characteristics so I’m focusing measurement attention where it matters most. I also document everything properly—recording measurements legibly, noting any borderline readings, flagging anything unusual. Good measurement discipline is what allows us to catch problems early and maintain process control. I’ve caught many potential quality issues through vigilant inspection that would have been expensive if they’d reached the customer.”

9. How do you communicate with other shifts and departments to ensure smooth operations?

Why ask this? Manufacturing runs 24/7 across shifts—effective communication prevents repeated problems, lost knowledge, and finger-pointing.

Sample Strong Answer: “Clear shift-to-shift communication is critical because the next operator is picking up exactly where I left off. I use our shift handover log religiously—documenting where we are in the production schedule, any quality issues I encountered and how I addressed them, any machine behavior that seems off, tooling that’s getting worn and will need changing soon, anything unusual. I don’t just write ‘everything’s fine’—I give specific, actionable information. If I make a process adjustment that improves cycle time or quality, I document it so the next shift can benefit. I also communicate proactively with maintenance about developing issues, with quality about borderline measurements or process capability concerns, and with planning when jobs are running ahead or behind schedule. I’ve learned that most production problems come from poor communication, not poor skills. When everyone shares information openly, we solve problems faster and prevent them from recurring. I see myself as part of a broader team, not just someone who works alone on my shift.”

10. Where do you see yourself growing in this field, and what skills are you working to develop?

Why ask this? This reveals motivation, growth mindset, and long-term potential—you want operators who will develop into leads, trainers, or specialists, not just clock-watchers.

Sample Strong Answer: “I’m passionate about manufacturing and see myself growing into more complex machining work and eventually a lead operator or setup specialist role. I’m actively working to expand my skills—I recently completed a blueprint reading and GD&T course at the community college, and I’m studying CNC programming on my own time using simulation software. My goal is to not just operate machines but to understand the entire manufacturing process from engineering to shipping so I can contribute to continuous improvement initiatives. I’d also like to get certified in Lean Manufacturing principles because I see opportunities for waste reduction and efficiency gains on every production floor I’ve worked on. Long-term, I could see myself in a manufacturing engineering technician role or training new operators. I believe in continuous learning because technology keeps evolving, and the operators who stay relevant are the ones who keep developing new capabilities. I’m looking for a company that values and supports that growth mindset.”

How CloudApper AI Recruiter Makes Hiring Machine Operators Effortless

Now here’s where manufacturing recruitment gets truly transformative: imagine having an intelligent AI recruiting assistant that engages every machine operator candidate instantly—24 hours a day, seven days a week—asks these exact technical interview questions (or your customized versions) via conversational text message, evaluates their responses for technical competence and cultural fit, and delivers a ranked shortlist of qualified candidates directly to your production managers.

That’s precisely what CloudApper AI Recruiter delivers for manufacturing facilities struggling to fill critical machine operator positions quickly while maintaining rigorous quality standards.

Here’s how our conversational AI chatbot revolutionizes machine operator recruitment:

Instant 24/7 Candidate Engagement

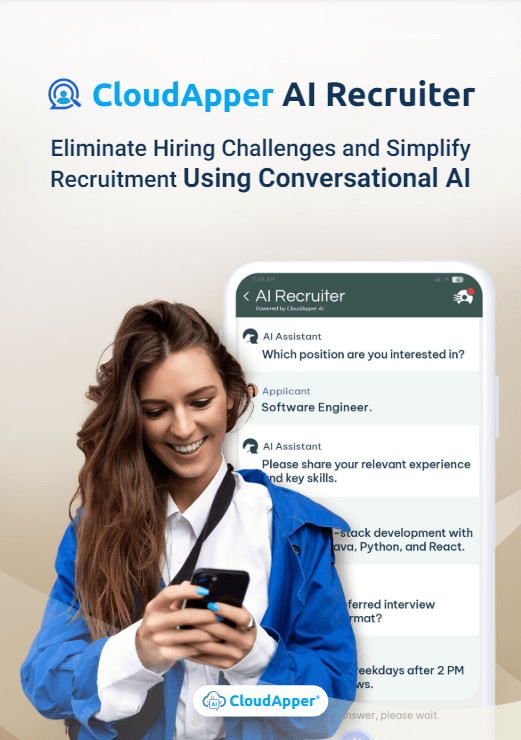

The moment someone applies for your machine operator position—whether through Indeed, LinkedIn, a QR code at a trade show, or an employee referral—CloudApper AI Recruiter engages them immediately in a natural, intelligent conversation. No more losing qualified CNC operators to competitors who respond faster. Our AI asks about their equipment experience, technical certifications, shift availability, troubleshooting capabilities, and measurement tool proficiency, then automatically scores responses based on your specific requirements and success profiles.

SMS-First Screening for Shift Workers

Machine operators work rotating shifts, nights, and weekends—they’re not sitting at computers during business hours. CloudApper AI Recruiter meets candidates where they are by conducting comprehensive screening interviews entirely via text message. Candidates can respond during breaks, commutes, or any convenient time, which increases completion rates to 87% (compared to 32% for traditional online applications) and dramatically reduces the candidate drop-off that cripples conventional hiring funnels.

Technical Skills Assessment Built For Manufacturing

Our platform includes specialized question banks covering CNC operation, manual machining, hydraulic and pneumatic systems, PLC basics, blueprint reading, GD&T interpretation, measurement tool proficiency, and preventive maintenance knowledge. You can customize questions for your specific equipment brands (Haas, Mazak, DMG Mori), processes (milling, turning, grinding, EDM), and materials (metals, composites, plastics). The AI even presents scenario-based technical questions—”Your part is consistently measuring 0.005″ over tolerance. Walk me through your troubleshooting process”—and evaluates responses for logical thinking and technical depth.

Bias-Free Evaluation & Compliance

Every candidate receives identical questions asked in the same professional manner, eliminating unconscious bias based on communication style, accents, age indicators, or personal rapport. CloudApper AI Recruiter evaluates responses objectively against job-relevant technical criteria, experience requirements, and behavioral indicators. This creates equitable hiring outcomes while strengthening your compliance posture with EEOC and OFCCP regulations—particularly important for government contractors.

Automated Shift Matching & Availability Screening

One of the biggest frustrations in manufacturing hiring is discovering late in the process that a strong candidate can’t work your required shifts. Our AI automatically captures detailed availability information—preferred shifts, weekend availability, overtime willingness, start date flexibility—and flags candidates whose schedules align with your open positions. This prevents wasted interview time and ensures you’re only talking to operators who can actually fill your needs.

Real-Time Ranking & Instant Manager Alerts

As candidates complete their AI screening interviews, CloudApper automatically ranks them using your weighted scoring criteria—maybe technical experience counts 40%, problem-solving ability 25%, quality consciousness 20%, and availability fit 15%. Your hiring managers receive instant mobile notifications when highly qualified candidates emerge, complete with interview transcripts, skill assessments, and hiring recommendations. The system can even automatically schedule shop floor tours or supervisor interviews based on mutual availability—reducing your average time-to-hire by 72%.

Proven Results from Manufacturing Leaders

A precision manufacturing company in Wisconsin specializing in medical device components recently implemented CloudApper AI Recruiter across their multi-shift operation. Within 120 days, they reduced average time-to-hire for CNC machine operators from 67 days to just 19 days, improved candidate quality ratings by 38%, and decreased 90-day turnover among new hires by 31%. Their lean HR team of three people went from being overwhelmed by phone screens and scheduling logistics to focusing exclusively on shop tours and final interviews with pre-qualified, technically vetted candidates.

Their Director of Operations told us: “We were bleeding production capacity because we couldn’t fill operator positions fast enough. By the time we’d screen and schedule candidates using traditional methods, they’d already accepted offers elsewhere. CloudApper’s instant engagement and automated technical screening changed everything. We’re now hiring faster, with better operator quality, and our existing team isn’t drowning in overtime anymore.”

Ready to eliminate your machine operator hiring bottlenecks and keep your production equipment running at full capacity? Discover how CloudApper AI Recruiter can transform your manufacturing recruitment from a constant struggle into a competitive advantage.

FAQ

Why are specialized interview questions critical for hiring machine operators?

Generic questions fail to assess essential technical skills like CNC setup, troubleshooting, GD&T interpretation, and preventive maintenance needed for modern manufacturing.

What modern skills do today’s machine operators need?

Beyond basic operation, they require PLC knowledge, digital literacy, blueprint/GD&T reading, diagnostic troubleshooting, quality inspection, and collaboration with automated systems.

How does CloudApper AI Recruiter address machine operator hiring challenges?

It provides instant 24/7 engagement via SMS, conducts technical interviews, scores responses objectively, matches shift availability, and ranks candidates—reducing time-to-hire and dropout rates.

Why do so many manufacturing candidates drop out of traditional hiring processes?

Slow response times, non-mobile-friendly applications, and rigid scheduling cause high abandonment, especially for shift workers not available during business hours.

How does AI screening improve fairness in machine operator hiring?

AI asks identical questions to all candidates and evaluates based solely on technical/job-relevant criteria, removing bias from communication style, accents, or rapport.

What results have manufacturers achieved with CloudApper AI Recruiter?

One company cut time-to-hire from 67 to 19 days, improved candidate quality by 38%, and reduced 90-day turnover by 31%.

Stop Losing Skilled Machine Operators to Slow Hiring

The shortage of qualified machine operators isn’t easing—but your hiring process can accelerate dramatically. With CloudApper AI Recruiter, you’ll engage technical candidates instantly, assess their capabilities thoroughly via conversational AI, and identify skilled operators who will maximize your equipment uptime, maintain quality standards, and contribute to operational excellence.

These 10 interview questions provide the framework for identifying machine operators who will thrive in your manufacturing environment. But conducting these assessments manually through endless phone screens, scheduling coordination, and inconsistent evaluation is exactly what’s keeping your critical positions open for months while production suffers and existing operators burn out.

Let AI handle the screening heavy lifting so your production managers can focus on meeting qualified operators in person and getting them trained and productive quickly.

Book a demo of CloudApper AI Recruiter today and see firsthand how conversational AI recruiting can transform your machine operator hiring. We’ll show you exactly how to customize the platform for your specific equipment types, technical requirements, and manufacturing environment—and get you operational in days, not months.

What’s your biggest frustration in hiring machine operators right now? Comment below and let’s discuss how AI-powered recruiting can solve your specific technical talent acquisition challenges.

You might also like to read:

10 Crucial Interview Questions for Warehouse Workers & Picker-Packers (+ AI Recruiter Automation)

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More

CloudApper AI Solutions for HR

- Works with

- and more.

Similar Posts

How cNPS Reflects Your Recruitment and Employer Brand

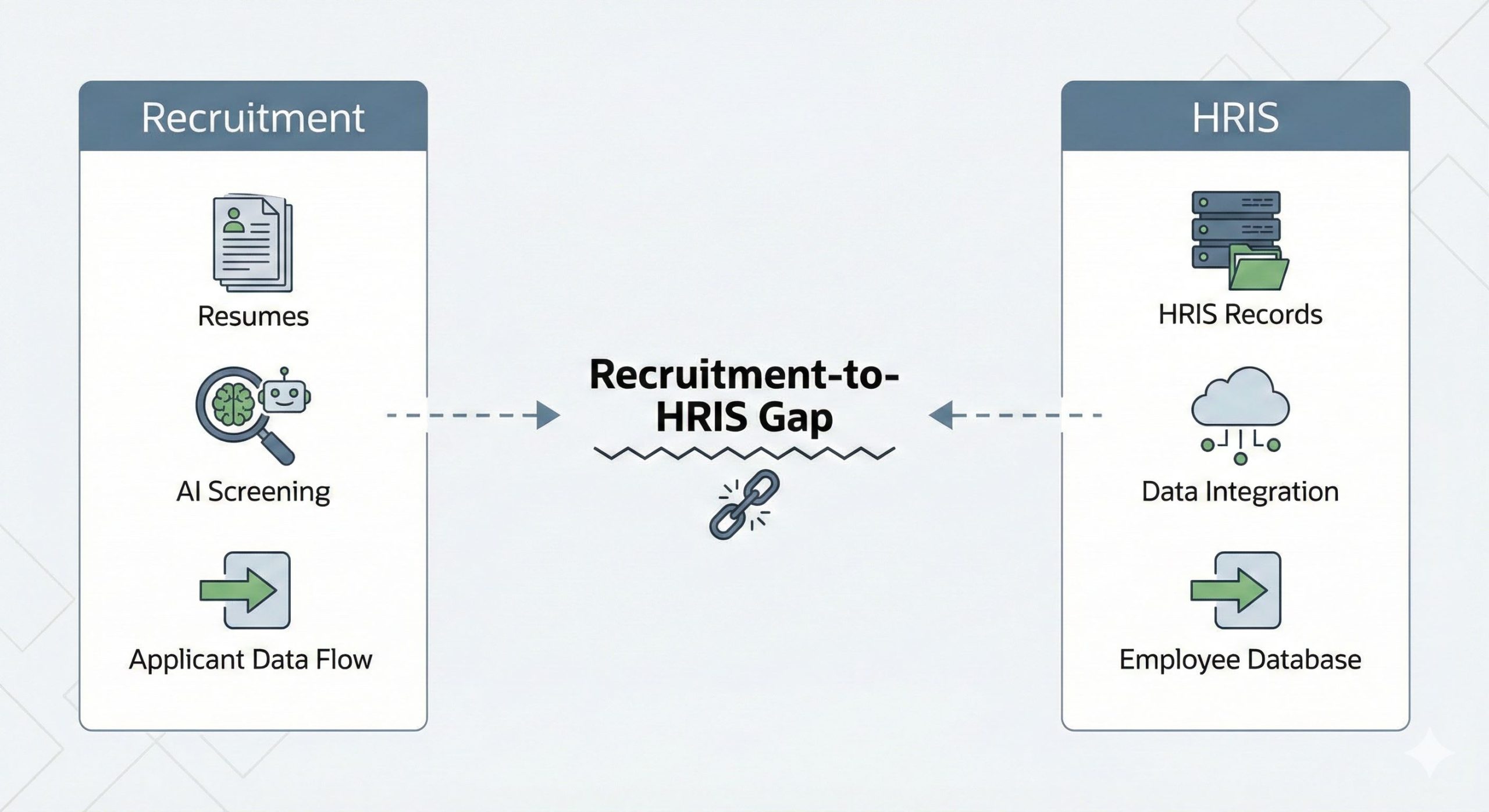

The Recruitment-to-HRIS Gap: Why Your “System of Record” Should Start…