Warehouse associates in last-mile logistics hubs face intense pressure with picking, packing, loading, and safety demands. These 10 essential warehouse associate interview questions help identify candidates who excel in fast-paced environments. Pair them with CloudApper AI Recruiter to automate screening, reduce hiring costs, and secure top talent quickly.

Table of Contents

Last-mile delivery hubs are the heartbeat of modern e-commerce, and warehouse associates are the workforce that keeps that heart pumping. Yet recruiting for these critical positions has become increasingly challenging. According to recent industry data, warehouse turnover rates average between 43-49% annually, with some last-mile operations experiencing turnover exceeding 60% during peak seasons. The math is brutal: if you operate a 200-person hub, you’re potentially replacing 100+ associates every year.

The hiring challenges compound quickly. Candidate drop-off rates for hourly warehouse positions exceed 70% in traditional application processes—primarily because slow, cumbersome hiring workflows lose candidates to competitors who move faster. The average cost to hire a warehouse associate ranges from $1,500 to $3,500 when you factor in advertising, screening time, drug testing, background checks, and training costs for employees who leave within 90 days. With tight labor markets, many hubs report receiving only 2-3 qualified applicants for every 10 positions they need to fill.

Meanwhile, the role itself has evolved dramatically. Today’s last-mile warehouse associates aren’t just picking and packing—they’re operating sophisticated warehouse management systems (WMS), using handheld RF scanners, meeting strict productivity metrics tracked in real-time, working in cross-functional teams during shift transitions, and adapting to rapidly changing volume demands that can triple during peak periods.

CloudApper AI Recruiter addresses these challenges head-on with conversational AI technology that engages candidates instantly via SMS or web chat, conducts intelligent screening interviews 24/7, and can complete what traditionally takes a week in under 24 hours—all while eliminating unconscious bias and ensuring every candidate receives consistent evaluation. Our logistics clients report screening 90% faster while significantly improving candidate quality and retention.

In this guide, we’ll give you the exact interview questions to identify high-performing warehouse associates for last-mile operations, plus show you how CloudApper AI Recruiter handles the heavy lifting so your team can focus on running operations instead of chasing applications.

TL;DR

Hiring reliable warehouse associates for last-mile hubs is tough amid high turnover. These 10 targeted warehouse associate interview questions assess safety, efficiency, teamwork, and adaptability. CloudApper AI Recruiter automates screening with conversational AI, slashing time-to-hire by up to 90% and improving hire quality in logistics.

Why These Questions Matter for Last-Mile Warehouse Associate Roles

The last-mile warehouse associate role has transformed significantly in the past five years. What was once primarily manual labor—loading trucks and moving boxes—now requires technological competency, productivity awareness, quality control precision, and teamwork in fast-paced, high-pressure environments. Modern last-mile hubs operate with sophisticated automation, real-time tracking systems, barcode scanning technology, and productivity metrics that measure performance down to units per hour.

Old-school questions like “Can you lift 50 pounds?” and “Are you available for the shift?” barely touch the surface of what predicts success in this environment. We need to assess adaptability to technology that changes frequently, ability to maintain pace and accuracy under pressure, teamwork and communication skills during chaotic peak periods, problem-solving when systems fail or issues arise, and most importantly—the reliability and work ethic that determine whether someone will show up consistently and meet productivity standards.

The questions below are specifically designed to reveal the qualities that separate adequate warehouse associates from exceptional ones: dependability, hustle mentality, quality consciousness, tech adaptability, safety awareness, and the resilience required to thrive in demanding last-mile operations where volume fluctuates wildly and every package matters.

Top 10 Essential Warehouse Associate (Last-Mile Hubs) Interview Questions (Plus How AI Recruiter Can Automate The Entire Hiring Process)

1. Describe your experience working in fast-paced environments where you had to meet specific productivity targets or deadlines. How did you ensure you stayed on pace?

Why ask this? Last-mile hubs operate on tight timelines with strict productivity expectations. This question reveals work ethic, self-management, and performance orientation.

Sample Strong Answer: “In my previous warehouse role, we had productivity targets of 250 units per hour during normal operations and 300+ during peak season. I approached it systematically—first, I learned the most efficient paths through the warehouse to minimize wasted steps. I organized my work area to keep everything I needed within easy reach. I also paid attention to my hourly performance on the scanner display and adjusted if I was falling behind. If I noticed I was slowing down mid-shift, I’d take a quick 2-minute stretch break to reset rather than powering through and getting progressively slower. I also learned which tasks I could batch together for efficiency—like scanning multiple items at once when possible. I consistently met or exceeded targets and was actually recognized as one of the top performers during our last peak season. I understand that in last-mile operations, delays cascade through the entire system, so maintaining pace isn’t just about personal performance—it’s about keeping the whole operation moving smoothly.”

2. Tell me about a time when you caught an error or quality issue before it became a bigger problem. What happened and what did you do?

Why ask this? Quality and accuracy directly impact customer satisfaction and operational costs. This reveals attention to detail and initiative.

Sample Strong Answer: “I was working in outbound sorting when I noticed a package that seemed unusually light for its size and label description. Instead of just scanning it through, I took a moment to check the label more carefully and realized it had been mis-sorted—the scan showed it was supposed to contain electronics, but it clearly didn’t feel right. I flagged my supervisor immediately, and when we opened it, we discovered it was actually an empty box that had been sealed by mistake earlier in the process. If that had gone out, it would have been a customer complaint, a lost product investigation, and probably a refund or replacement—all expensive problems. My supervisor appreciated that I caught it, and it reminded me why those quick verification checks matter even when we’re moving fast. I’ve learned that taking an extra two seconds to verify something suspicious actually saves time in the long run compared to dealing with returns, mis-ships, and customer issues. Quality and speed aren’t opposing goals—you need both to run an effective operation.”

3. How comfortable are you with technology like handheld scanners, warehouse management systems, and learning new software or equipment?

Why ask this? Technology is integral to modern warehouse operations. Tech-resistant candidates create bottlenecks and errors.

Sample Strong Answer: “I’m very comfortable with warehouse technology and actually prefer it because it makes tracking and accuracy much easier. I’ve used several different RF scanner systems—Zebra handheld devices primarily—for scanning, inventory tracking, and order verification. I’m familiar with basic WMS functions like picking orders, confirming loads, and marking tasks complete. I’ve also used tablet-based systems for clocking in/out and accessing shift information. When I started my last job, they were transitioning to a new scanning system with different screens and workflows. I made sure to attend all the training sessions, practiced during slower periods, and asked questions when I was unsure. Within a week, I was as fast on the new system as I’d been on the old one. I understand that technology in warehouses evolves constantly—new equipment, software updates, process changes—and I’m totally fine with that. I’m someone who reads instructions, practices new procedures, and adapts quickly. If there’s specific technology your facility uses, I’m confident I can learn it quickly and use it effectively.”

4. Last-mile hubs often have significant volume fluctuations—slow periods and intense peak seasons. How do you handle the shift between these different operational paces?

Why ask this? Volume volatility is defining characteristic of last-mile operations. This question assesses adaptability and stamina.

Sample Strong Answer: “I actually appreciate the variety that comes with volume changes—it keeps the work interesting and challenging. During slower periods, I focus on being thorough with quality checks, keeping my work area organized, helping with inventory tasks, and offering to assist in other departments if needed. I see slower times as opportunities to learn additional skills that make me more versatile. During peak seasons, my mentality shifts to efficiency and endurance. I know those periods might mean 10-12 hour shifts, working weekends, and maintaining high pace for weeks at a time. I prepare myself physically—getting good sleep, eating properly, staying hydrated—because I know the work is demanding. Mentally, I stay focused on the bigger picture: peak season is when the company needs reliable people most, and I take pride in being someone management can count on during crunch time. In my last role, I worked through two holiday peak seasons without missing a shift and maintained above-average productivity even when we were at 200% normal volume. I understand that consistency across both high and low volume periods is what makes a valuable warehouse associate.”

5. Describe a situation where you had to work as part of a team to complete a time-sensitive task. What was your role and how did the team succeed?

Why ask this? Last-mile operations require seamless teamwork during shift changes, loading operations, and problem resolution.

Sample Strong Answer: “We had a situation where an inbound trailer arrived two hours late, which put us behind schedule for our outbound departure windows. Our supervisor gathered the team and explained we needed to unload, sort, and stage 1,500 packages in about half the usual time to avoid delaying drivers. Instead of everyone working independently, we reorganized as an assembly line—I volunteered to be one of the unloaders because I knew I could work at a fast pace, while team members who were better at sorting took those positions, and our most detail-oriented people handled staging and verification. We communicated constantly—calling out package types, alerting each other to fragile items, and keeping each other updated on progress. Everyone stayed focused and pushed hard, and we actually completed the entire process with 10 minutes to spare. What made it work was clear communication, people working to their strengths, and everyone committing to the shared goal. Nobody complained or slacked off—we all understood the situation and pulled together. That’s the kind of team environment I thrive in, and I know last-mile operations require that kind of collaboration especially during peak times or when unexpected issues arise.”

6. Safety is critical in warehouse environments. Tell me about your approach to working safely and how you’ve handled safety concerns you’ve observed.

Why ask this? Warehouse injuries are costly and disruptive. Safety-conscious employees protect themselves and their coworkers.

Sample Strong Answer: “Safety is non-negotiable for me because I’ve seen what happens when people get complacent. My approach starts with following all protocols every single time—proper lifting technique with my legs not my back, wearing required PPE like safety shoes and high-vis vests, staying aware of my surroundings especially around powered equipment, and never taking shortcuts that create risk. I pay attention during safety briefings even when they’re repetitive because that’s often when they’re emphasizing something important. I’ve also spoken up when I’ve seen safety issues. There was an incident where I noticed a spill in a walkway that wasn’t marked. Rather than assuming someone else would handle it, I immediately put up caution cones and notified a supervisor so it could be cleaned properly. I’ve also politely reminded coworkers when I’ve seen them lifting incorrectly or standing in blind spots near forklifts—it’s not about being bossy, it’s about everyone going home healthy every day. I’ve completed forklift safety training and general warehouse safety certifications in my previous roles. I understand that in busy operations, there’s pressure to move fast, but speed is never worth an injury that could end someone’s career or create serious problems for the team and company.”

7. Tell me about a time when equipment failed or you encountered a technical problem during your shift. How did you respond?

Why ask this? Technical issues are inevitable. This reveals problem-solving, initiative, and communication instincts.

Sample Strong Answer: “I was in the middle of a picking assignment when my RF scanner froze completely—wouldn’t scan, wouldn’t respond to any inputs, just stuck on one screen. This was during peak season when every minute mattered. First, I tried the basic troubleshooting I’d been trained on—power cycle, checking the battery connection, and trying to restart the application. When that didn’t work after about two minutes, I immediately walked to my supervisor rather than wasting more time. I explained the situation clearly, showed them what was happening, and they got me a replacement scanner and reassigned the frozen unit to IT. The key was that I swapped my task assignment to the new device and was back working within five minutes. I’ve learned that when technical issues arise, you try quick fixes but don’t waste significant time—escalate to people who can actually resolve it while you stay productive. I also documented the issue in our end-of-shift report so IT could track the problem device. In warehouse operations, downtime cascades quickly, so responding efficiently to technical problems is critical. I’m comfortable with basic troubleshooting, but I also know when to escalate and keep moving rather than letting a technical issue derail my entire shift.”

8. How do you maintain focus and accuracy during repetitive tasks over long shifts, especially when you’re working on something like sorting or scanning for hours at a time?

Why ask this? Repetitive work challenges concentration. Maintaining accuracy despite monotony separates strong performers from weak ones.

Sample Strong Answer: “I’ve learned strategies to stay engaged even during repetitive tasks. First, I set personal mini-goals throughout my shift—like trying to improve my scan accuracy to 99.9% for the next hour, or challenging myself to maintain a specific pace. This turns repetitive work into a personal performance game. I also stay mentally active by being observant—noticing patterns, identifying opportunities for efficiency improvements, and staying aware of what’s happening around me rather than just zoning out. Taking my scheduled breaks is important too; those 10-15 minute resets help me come back focused for the next section of my shift. I also vary my body position slightly when possible—shifting weight, adjusting my stance—to avoid physical fatigue that affects mental focus. In my previous role, I worked in outbound sorting which is extremely repetitive—scanning and diverting packages for 8+ hours. I maintained 99.7% accuracy over six months, which was above facility average. The key is treating every package or item as important even if it’s the 500th one you’ve touched that day, because that one error could be the one that causes a customer problem. I take pride in consistency and I’ve developed the mental discipline to maintain it even during long, repetitive shifts.”

9. Peak season often means mandatory overtime, weekend work, and schedule changes with short notice. How flexible is your schedule, and how do you handle changing demands?

Why ask this? Schedule flexibility is essential for last-mile operations. Inflexible candidates create staffing gaps when you need them most.

Sample Strong Answer: “I understand that last-mile operations are driven by customer demand and volume that fluctuates significantly, especially during holidays. My schedule is flexible and I’m prepared for the demands of peak season. I’m available for mandatory overtime, weekend shifts, and schedule adjustments—I actually plan my personal life around the expectation that November and December will be all-hands-on-deck periods. I don’t have childcare conflicts or other obligations that would prevent me from working extended hours when needed. During peak season at my last job, I worked several 60-hour weeks including weekends for about six weeks straight. It’s demanding, but I went in with the right mindset knowing it was temporary and necessary. I made sure I was taking care of myself—sleep, nutrition, hydration—so I could sustain that pace without burning out. I also understand that in this industry, emergency volume surges or operational issues might mean short-notice schedule changes, and I’m fine with that flexibility. I check my schedule regularly and respond quickly to shift pickup requests or schedule change notifications. I’m looking for a role where I’m a dependable member of the team, and that means being available when the operation needs me most, not just when it’s most convenient for me.”

10. Why do you want to work in a last-mile warehouse specifically, and what are your career goals in logistics?

Why ask this? This reveals motivation, retention potential, and whether they understand what they’re signing up for versus just needing any job.

Sample Strong Answer: “I’m specifically interested in last-mile warehouse work because I like the energy and pace of operations that directly connect to customers. There’s something satisfying about knowing the packages I’m handling are going to reach someone that same day or next day—there’s a tangible impact to the work. I also appreciate that last-mile facilities tend to have clear performance metrics and advancement opportunities for people who demonstrate reliability and strong performance. I’ve researched your company specifically and I’m impressed by your growth in the market and your reputation for promoting from within. Short-term, my goal is to establish myself as one of your most dependable, high-performing associates—someone who shows up on time every shift, consistently meets or exceeds productivity targets, maintains quality standards, and steps up during peak seasons. I want to be someone supervisors know they can count on. Long-term, I’m interested in growing within logistics. I’d like to learn different departments—inbound, outbound, inventory control—to build a comprehensive understanding of the operation. Eventually, I’d be interested in moving into a lead position or specialist role where I could help train new associates or contribute to operational improvements. I’m not just looking for a paycheck—I’m looking for a company where hard work gets recognized and there’s a path to grow. Everything I’ve learned about your operation suggests that’s possible here.”

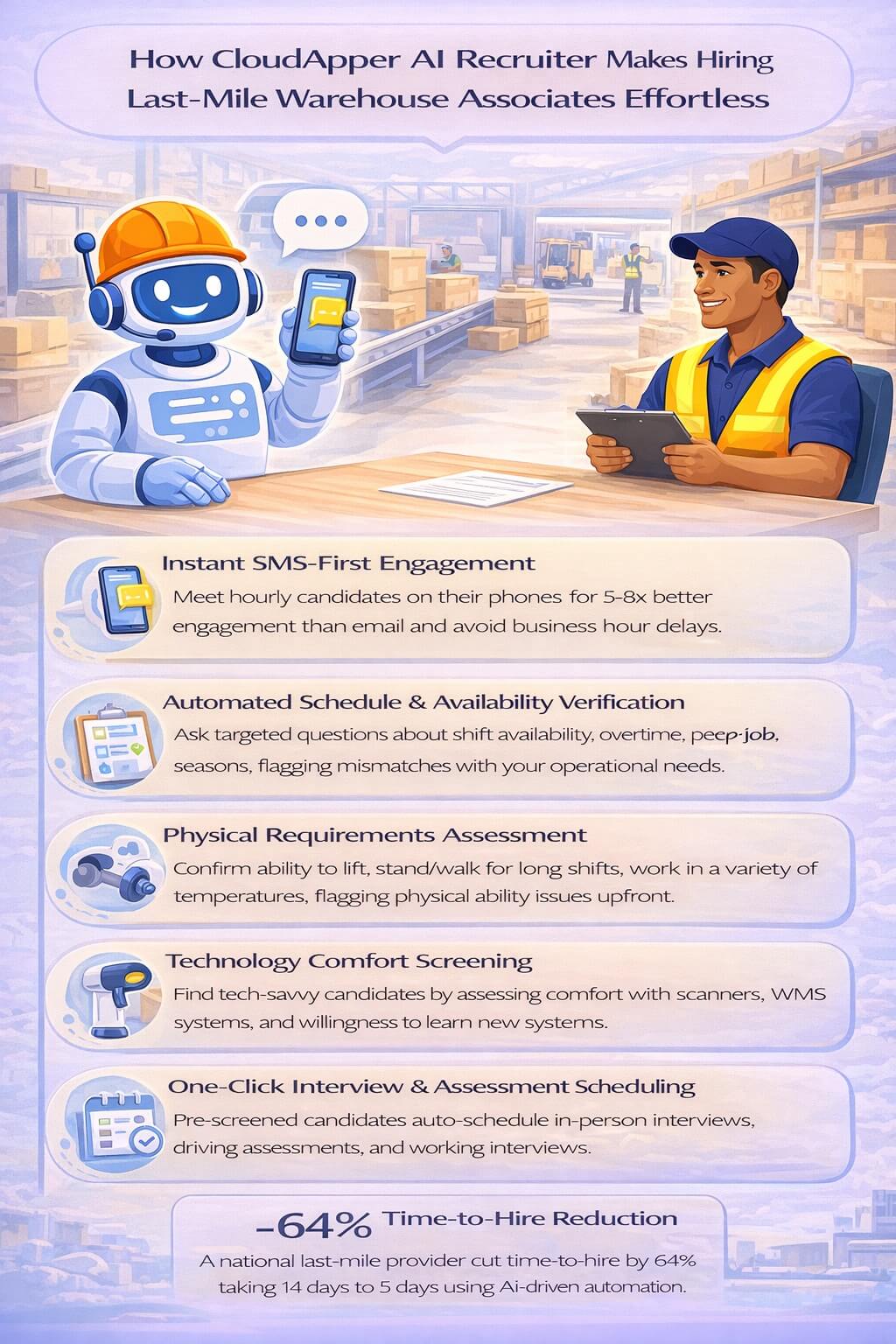

How CloudApper AI Recruiter Makes Hiring Last-Mile Warehouse Associates Effortless

Here’s the challenge every last-mile operations manager faces: you need to hire constantly to maintain staffing levels in the face of 40-60% annual turnover, process hundreds of applications during peak season ramp-ups, screen candidates quickly before they accept offers elsewhere, and identify people who’ll actually show up and perform—all while running your daily operations and managing everything else that comes with logistics leadership.

CloudApper AI Recruiter solves this impossible equation by automating the entire initial screening process with conversational AI that engages candidates 24/7. Here’s exactly how it transforms warehouse associate hiring:

The moment a candidate applies—whether through your website, job boards, or text-to-apply campaigns—CloudApper’s AI chatbot engages them immediately via SMS or web chat. No waiting for business hours, no applications sitting unreviewed for days while candidates lose interest or accept other offers. The AI conducts a natural, conversational screening interview asking these exact questions (or your customized versions), intelligently adapting follow-up questions based on responses just like an experienced recruiter would.

Key features specifically designed for warehouse associate recruitment:

- Instant SMS-First Engagement: Meet hourly candidates where they are—on their phones. Text-based screening achieves 5-8x higher engagement rates than email-based systems, critical for hourly workers who often apply via mobile devices

- Automated Schedule & Availability Verification: The AI asks detailed questions about shift availability, overtime flexibility, weekend work, and peak season commitment, immediately flagging candidates whose availability doesn’t match your operational needs

- Physical Requirements Assessment: Built-in questions confirm ability to lift 50+ pounds repeatedly, stand/walk for 8-12 hour shifts, work in varying temperatures, and meet physical demands—ensuring candidates understand job realities before proceeding

- Technology Comfort Screening: Custom questions assess comfort with scanners, WMS systems, and learning new technology, helping you identify tech-resistant candidates who’ll struggle in modern warehouse environments

- Reliability & Work History Analysis: The AI probes employment stability, reasons for leaving previous positions, attendance records, and commitment to schedule adherence—key predictors of warehouse associate retention

- One-Click Interview & Assessment Scheduling: Qualified candidates are automatically routed to calendar scheduling for in-person interviews, facility tours, or working interviews, eliminating coordination bottlenecks

Real-world impact: A national last-mile logistics provider with 15 hub locations implemented CloudApper AI Recruiter to address their chronic understaffing issues and 55% annual turnover rate. Within 90 days, they reduced time-to-hire from 14 days to just 5 days while improving 90-day retention by 28%. Their talent acquisition team went from conducting 200+ phone screens weekly to focusing exclusively on final interviews with pre-qualified candidates who’d already demonstrated strong fit through AI screening.

The breakthrough came from 24/7 engagement capability. They discovered that 62% of their successful hires completed AI screening outside traditional business hours—late evenings, weekends, and overnight when shift workers are often job searching. These candidates would have been completely lost with traditional 9-5 recruiting workflows, representing nearly two-thirds of their hiring volume.

The AI system also standardized evaluation, asking every candidate identical questions in the same way with consistent scoring criteria. This eliminated unconscious bias, improved compliance documentation, and actually resulted in more diverse hiring outcomes—candidates were evaluated purely on qualifications, availability, and fit rather than factors unrelated to job performance.

For last-mile operations competing in brutal labor markets, CloudApper AI Recruiter isn’t just an efficiency tool—it’s the difference between maintaining adequate staffing levels or constantly operating short-handed with the operational chaos that creates.

Frequently Asked Questions

1. Why are behavioral interview questions critical for warehouse associate roles?

Behavioral questions uncover how candidates handled real scenarios like heavy lifting, tight deadlines, or safety incidents—strong predictors of performance in demanding last-mile warehouse environments.

2. How can I assess a warehouse associate’s safety awareness during an interview?

Ask about prior safety training, hazard identification, proper lifting techniques, and incident reporting. Top candidates prioritize safety protocols and demonstrate proactive risk awareness.

3. What questions evaluate a candidate’s ability to work in a fast-paced warehouse?

Probe experiences with high-volume picking/packing, meeting productivity targets, and adapting to shifting priorities—key for last-mile hubs with peak-season surges.

4. How do I gauge teamwork and communication skills for warehouse roles?

Use scenarios involving coordination with loaders, drivers, or supervisors. Look for examples of clear communication, conflict resolution, and supporting team goals.

5. Why ask about physical stamina and endurance in warehouse associate interviews?

These roles require prolonged standing, lifting 50+ lbs, and repetitive motions. Questions confirm candidates understand physical demands and have relevant experience.

6. How does CloudApper AI Recruiter automate warehouse associate hiring?

It uses 24/7 conversational AI via SMS/web chat to engage applicants, screen for licenses, physical ability, and experience, verify details, and schedule interviews—often completing the process in under 24 hours.

7. What benefits does AI recruiting offer for high-volume warehouse positions?

Reduces time-to-hire by 90%, lowers cost-per-hire (from $1,500–$4,000), eliminates bias, boosts application conversion, improves retention by 35%, and captures off-hours candidates.

8. Can CloudApper handle seasonal or peak hiring surges for last-mile warehouses?

Yes—it scales instantly to screen thousands of applicants, asks role-specific follow-ups (e.g., forklift experience, availability), and maintains consistent evaluation during high-volume periods.

9. How does AI ensure fair and unbiased screening for warehouse associates?

Standardized conversational questions focus purely on qualifications, experience, and skills—removing human bias from initial reviews and promoting diverse hires.

10. Is CloudApper AI Recruiter suitable for small logistics operations or only large fleets?

Fully scalable—small warehouses gain fast, affordable hiring; larger last-mile hubs manage volume efficiently without overwhelming HR teams.

11. How quickly can CloudApper reduce warehouse hiring timelines?

Clients report cutting time-to-hire from weeks to days (e.g., 21 to 7 days), helping secure candidates before competitors in a tight labor market.

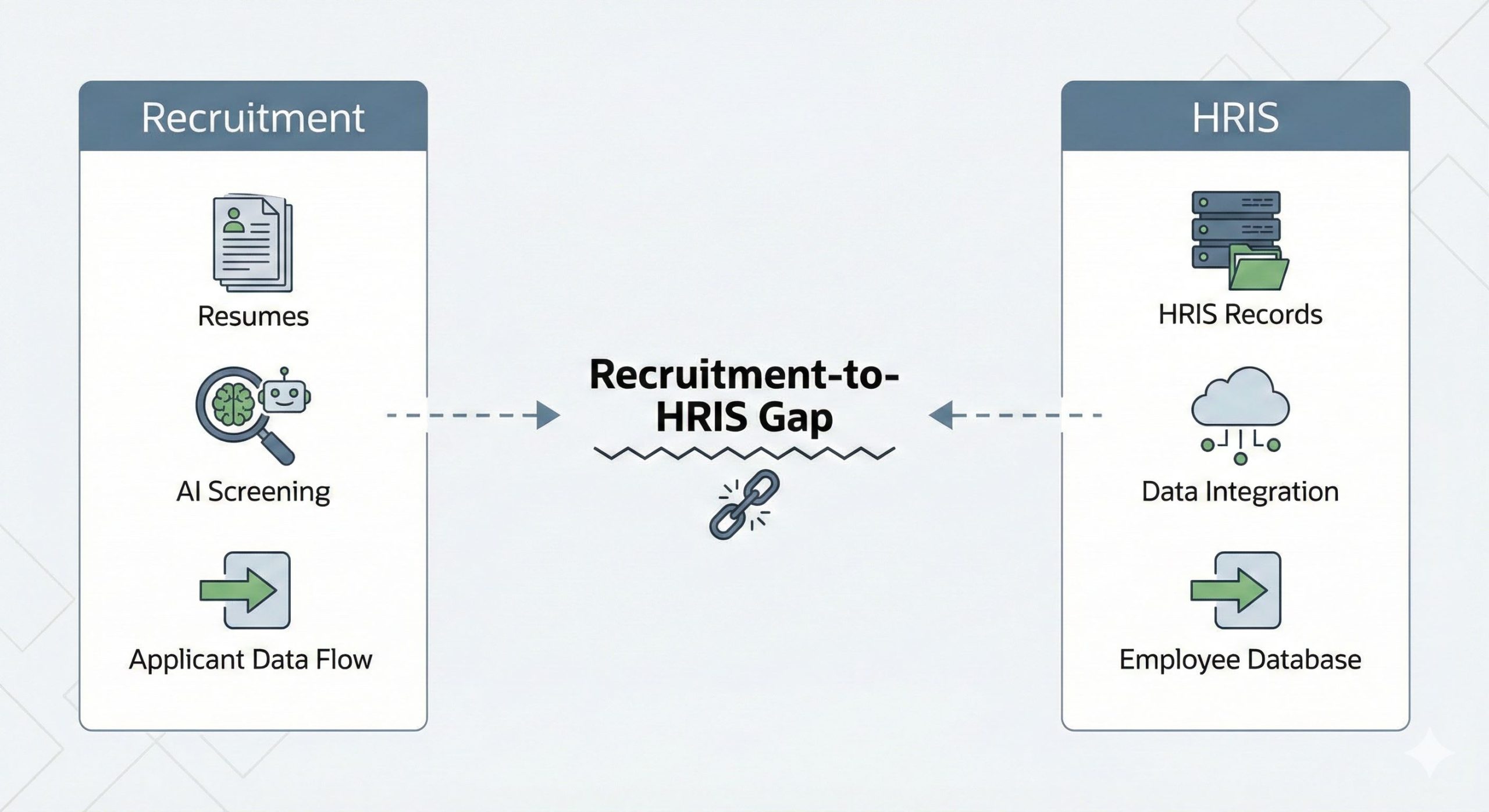

12. Does CloudApper integrate with existing ATS or job boards for warehouse recruitment?

Yes—seamless integration automates outreach, screening, and data sync across popular platforms for streamlined warehouse associate hiring.

Ready to Transform Your Warehouse Associate Hiring?

Chronic understaffing doesn’t have to be your reality. Stop losing qualified candidates to competitors who engage faster. Stop burning your operations team’s time conducting hundreds of phone screens. Stop watching your turnover remain stubbornly high while hiring costs continue climbing.

CloudApper AI Recruiter gives you the speed, consistency, and 24/7 engagement capacity to win the warehouse talent war while dramatically reducing recruiting costs and improving retention. Our last-mile logistics clients are filling warehouse positions 70% faster with candidates who stay longer and perform better.

Book a personalized demo today and we’ll show you exactly how operations like yours are automating screening, engaging candidates instantly via SMS, and building stronger warehouse teams. We’ll customize the platform with your specific questions, shift requirements, and workflow—and you’ll see firsthand how AI recruiting solves the staffing challenges that have plagued last-mile operations.

What warehouse associate interview questions have worked best for your hiring? Share your insights in the comments below—we’d love to learn what’s working in today’s competitive labor market!

You might also like to read:

10 Crucial Interview Questions for Dispatch Coordinator in Transportation & Logistics Industry with AI Recruiter Automation

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More

CloudApper AI Solutions for HR

- Works with

- and more.

Similar Posts

How cNPS Reflects Your Recruitment and Employer Brand

The Recruitment-to-HRIS Gap: Why Your “System of Record” Should Start…