Manufacturing faces a growing shortage of qualified quality control inspectors amid rising standards and retirements. These 10 targeted questions assess metrology expertise, GD&T knowledge, statistical skills, and integrity. CloudApper AI Recruiter automates 24/7 SMS screening, ranks candidates objectively, and cuts time-to-hire by 74% for stronger quality teams.

Table of Contents

Quality control inspectors are the gatekeepers of manufacturing excellence, yet they’re becoming increasingly difficult to hire and retain. According to the American Society for Quality, 73% of manufacturing companies report significant challenges finding qualified quality professionals, with the average cost to hire a skilled QC inspector now exceeding $7,800 when factoring in recruiting expenses, training investments, and the production disruptions caused by understaffed quality departments during the typical 68-day hiring cycle.

For more information on CloudApper AI Recruiter visit our page here.

The stakes couldn’t be higher. A single quality escape—defective products reaching customers—can cost manufacturers hundreds of thousands in recalls, warranty claims, and irreparable brand damage. Yet quality departments are chronically understaffed as experienced inspectors retire and younger workers gravitate toward roles perceived as more technologically advanced. The American Society for Quality projects a 50,000-person shortage of quality professionals by 2026, creating intense competition for qualified QC inspectors across all manufacturing sectors.

The role itself has evolved dramatically. Today’s quality control inspectors need far more than keen eyesight and measuring tools. They must navigate sophisticated coordinate measuring machines (CMM), statistical process control software, digital quality management systems, understand complex GD&T specifications, interpret ISO and industry-specific standards, and communicate effectively with engineering, production, and supplier quality teams. Traditional interview approaches focused on attention to detail and measurement experience miss these critical technical and analytical competencies.

Candidate experience issues compound the talent shortage. Research indicates that 59% of quality professional candidates abandon manufacturing hiring processes before completion, citing slow response times, poor communication, and scheduling difficulties as primary frustrations. When a certified quality engineer applies to multiple companies, the organization that engages them immediately and respects their time wins the talent war.

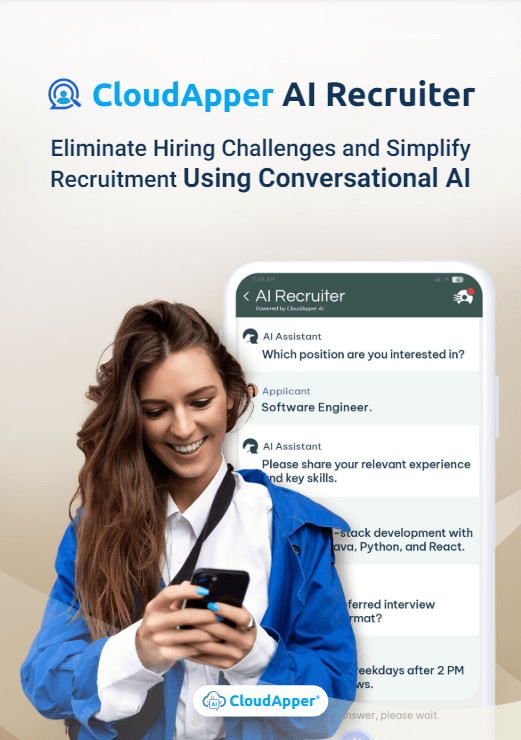

That’s exactly why forward-thinking manufacturing quality leaders are deploying CloudApper AI Recruiter, a conversational AI chatbot that screens quality control inspector candidates 90% faster than traditional methods, eliminates unconscious bias, and conducts sophisticated technical interviews 24/7 via text message or web chat. Instead of losing qualified QC professionals to competitors with faster, more responsive processes, our AI engages them within minutes, asks role-specific technical and behavioral questions, assesses analytical thinking, and surfaces only the most qualified candidates for your quality managers to meet.

In this comprehensive guide, we’ll give you the exact interview questions you need to identify meticulous, technically competent quality control inspectors who will protect your brand reputation and drive continuous improvement—plus show you how AI handles the heavy lifting of candidate outreach, engagement, screening, and evaluation so you can build the quality team your operations demand.

TL;DR

Quality control inspectors are increasingly hard to hire as roles demand advanced technical and analytical skills. Use these 10 key interview questions to evaluate measurement proficiency, GD&T understanding, statistical methods, and quality mindset. CloudApper AI Recruiter revolutionizes hiring with instant text-based screening, bias-free technical assessments, certification verification, and real-time ranking—reducing time-to-hire by 74%.

Why These Questions Matter for Quality Control Inspectors

The quality control inspector role has transformed from primarily visual inspection and go/no-go gauging to sophisticated technical work requiring metrology expertise, statistical analysis, root cause investigation, and cross-functional collaboration. Generic interview questions like “What are your strengths?” or “Why quality control?” fail to assess the specific competencies that differentiate exceptional inspectors from those who simply check boxes. Modern QC inspectors must proficiently operate advanced measurement equipment, interpret complex engineering specifications including GD&T, apply statistical methods to identify process trends, use quality management software systems, communicate findings diplomatically to production teams, participate in corrective action investigations, and maintain meticulous documentation for regulatory compliance and customer audits. The best quality control inspector interview questions probe technical knowledge depth, attention to detail, analytical problem-solving, integrity when facing pressure to pass questionable parts, communication skills, and continuous improvement mindset. These targeted questions help you identify candidates who won’t just catch defects—they’ll prevent them through proactive process monitoring, data analysis, and collaborative problem-solving that elevates your entire quality culture.

Top 10 Essential Quality Control Inspector Interview Questions (Plus How AI Recruiter Can Automate The Entire Hiring Process)

1. Describe your experience with measurement equipment and inspection techniques. What tools are you proficient with?

Why ask this? This establishes baseline technical capabilities and helps you assess whether their hands-on metrology experience aligns with your inspection requirements and equipment portfolio.

Sample Strong Answer: “I have extensive experience with both traditional and advanced measurement equipment. For everyday inspections, I’m proficient with micrometers, calipers, height gauges, pin gauges, thread gauges, and optical comparators. I understand proper measurement technique—calibration verification, cleaning procedures, appropriate measuring force, and taking multiple readings for consistency. For more complex inspection work, I’m trained on coordinate measuring machines—I can write basic inspection programs, perform part setup and alignment, and interpret CMM reports. I’ve also used vision systems for automated inspection, surface roughness testers, and hardness testers. I’m comfortable with both first-article inspection of new parts and in-process statistical sampling. I understand the importance of measurement uncertainty and using the right tool for the tolerance requirements—you don’t use a tape measure for a ±0.001″ tolerance. I also maintain inspection equipment properly and understand gage R&R studies to verify measurement system capability.”

2. How would you explain GD&T and why it’s important in quality inspection?

Why ask this? GD&T knowledge is essential for modern manufacturing—this assesses whether candidates truly understand geometric tolerancing or just claim familiarity on their resume.

Sample Strong Answer: “Geometric Dimensioning and Tolerancing is a symbolic language that defines the allowable variation in the geometry of parts. It’s important because traditional plus/minus tolerancing doesn’t adequately control how features relate to each other in 3D space—things like perpendicularity, position, profile, and runout. GD&T uses feature control frames with datums to specify exactly how parts should be measured and what constitutes acceptable variation. As an inspector, I need to understand GD&T to properly set up my inspection equipment, establish the correct datum reference frame, and verify that parts meet the functional requirements the engineer intended. For example, a positional tolerance on a hole pattern tells me not just where the holes should be, but how much they can vary while still allowing assembly. I’ve been trained in GD&T fundamentals and have practical experience interpreting drawings with geometric callouts and performing functional gauging and CMM inspection based on those requirements.”

3. Walk me through how you would conduct a first-article inspection on a new part.

Why ask this? First-article inspection is critical for new part qualification—this reveals process discipline, technical competence, and thoroughness that prevents costly production launches with undiscovered issues.

Sample Strong Answer: “First-article inspection is comprehensive because it’s our opportunity to verify a new part before production begins. I start by thoroughly reviewing the drawing, specification, and any customer-specific requirements to understand all the critical characteristics and their acceptance criteria. I verify I have calibrated inspection equipment appropriate for the tolerances. I create or review the inspection plan to ensure we’re measuring everything required. During inspection, I measure every dimension and characteristic called out on the drawing, not just a sample—first article is 100% inspection. I document everything in the inspection report with actual measurements, not just pass/fail, because engineering needs that data. If I find any nonconformances, I document them clearly and work with engineering to determine if they’re acceptable deviations or if the part needs rework or the process needs correction. I also check for workmanship issues that might not have specific dimensions—burrs, surface finish, cleanliness. The goal is to catch any problems before we commit to production volumes, because it’s much easier to fix issues on one part than on a thousand.”

4. Describe a time when you identified a quality issue that others had missed. What did you do?

Why ask this? This behavioral question reveals attention to detail, initiative, and whether candidates take ownership of quality beyond minimum requirements.

Sample Strong Answer: “Several months ago, I was performing routine receiving inspection on machined castings from a supplier we’d worked with for years. The parts were passing all the dimensional checks, but something didn’t look quite right—the surface texture in certain areas seemed rougher than usual. This wasn’t a controlled characteristic with a specification, just my experience telling me something was different. I brought it to my supervisor’s attention and we decided to sectioning one part to look at the subsurface. We discovered micro-porosity that would have caused premature failure in service. Turns out the supplier had changed their casting parameters without notifying us. We quarantined the entire lot, worked with the supplier to correct their process, and implemented a visual check for surface texture in our incoming inspection procedure. That experience reinforced for me that quality inspection isn’t just about hitting the measurements—it’s about being observant and trusting your instincts when something doesn’t seem right, even if it technically passes the documented checks.”

5. How do you use statistical methods in quality control? Can you give me an example?

Why ask this? Modern quality control relies on statistical thinking—this assesses analytical capabilities beyond basic pass/fail inspection.

Sample Strong Answer: “Statistical methods are essential for understanding process capability and identifying trends before they become problems. I routinely use control charts—X-bar and R charts primarily—to monitor critical characteristics during production runs. The charts tell me not just whether parts are in tolerance, but whether the process is stable and capable. For example, in my last role, I was monitoring a critical diameter on a turned part. Even though all the parts were passing inspection, my control chart showed the average was slowly drifting upward toward the upper tolerance limit. I brought this to the production supervisor’s attention, and we discovered gradual tool wear. By catching it early through statistical monitoring, we avoided producing out-of-spec parts and implemented a tool change schedule based on data rather than just running until we got failures. I also understand process capability indices—Cp and Cpk—and how to interpret capability studies to determine if a process can reliably meet requirements. Statistics transform quality control from reactive inspection to proactive process monitoring.”

6. Tell me about a situation where production pressured you to accept questionable parts. How did you handle it?

Why ask this? This critical question reveals integrity, backbone, and commitment to quality standards when facing pressure—essential traits for QC inspectors.

Sample Strong Answer: “Integrity is non-negotiable in quality control. I had a situation where we were running behind on a large customer order and the production supervisor asked me to ‘use my judgment’ on some parts that were slightly out of tolerance on a non-critical dimension. I explained that I don’t have authority to accept out-of-spec parts—that requires a material review board decision with engineering and quality management input. I documented the nonconformance, quarantined the affected parts, and initiated the proper review process. I understood the production pressure, but I also understood that my job is to protect the company and the customer by enforcing specifications. In this case, engineering determined the deviation was acceptable and issued a concession for that lot, so production got their parts. But if I’d just passed them without proper authorization, I would have violated our quality system and potentially put the customer at risk. I’ve learned that short-term production pressure can never justify compromising quality standards—the consequences of a quality escape are far worse than a temporary schedule delay.”

7. How do you stay current with quality standards, regulations, and inspection techniques?

Why ask this? Quality standards evolve constantly—this assesses professional commitment and continuous learning mindset essential for quality careers.

Sample Strong Answer: “Quality is a profession that requires continuous learning, and I take that seriously. I maintain my ASQ Certified Quality Inspector certification, which requires ongoing professional development. I regularly read Quality Magazine and ASQ publications to stay current on new inspection technologies and methodologies. I’ve taken online courses in advanced GD&T and statistical process control to deepen my technical knowledge. When our facility implemented new ISO 9001:2015 requirements, I volunteered to be part of the implementation team to understand the changes thoroughly. I also network with other quality professionals through local ASQ chapter meetings where we share challenges and solutions. In terms of specific skills, I’ve been learning more about automated vision inspection systems because I see that as the future of high-volume inspection. I believe that to be valuable as a quality professional, you need to evolve your skills as technology and standards evolve—complacency is not an option in quality control.”

8. Describe your experience with quality management systems and documentation requirements.

Why ask this? Proper documentation is critical for traceability, audits, and continuous improvement—this assesses discipline and understanding of quality systems beyond just measurement.

Sample Strong Answer: “I have extensive experience working within ISO 9001 quality management systems and understand that documentation is just as important as the inspection itself. I’m proficient with quality management software—I’ve used systems like QT9, ETQ, and SAP Quality Management for recording inspection results, managing nonconformances, tracking corrective actions, and generating quality reports. I understand the importance of accurate, legible, contemporaneous records—you document as you inspect, not from memory later. I’m careful to record actual measurements, not just checkmarks, because that data is valuable for trend analysis and process capability studies. I also understand document control—using the correct revision of inspection procedures and work instructions, and following proper protocols when procedures need updating. For customer audits and certifications, I know how to maintain inspection records, calibration certificates, and material certifications in organized, retrievable formats. Good documentation isn’t just bureaucracy—it’s how we prove that our quality system actually functions and how we can investigate issues when they occur.”

9. How would you handle a situation where you suspect inspection equipment is providing inaccurate readings?

Why ask this? Measurement system integrity is fundamental—this assesses technical judgment, problem-solving, and commitment to accurate data over convenient results.

Sample Strong Answer: “Measurement system reliability is absolutely critical because we make accept/reject decisions based on that data. If I suspected equipment inaccuracy, I would stop using it immediately and tag it out of service—continuing to use questionable equipment would make all subsequent inspection results invalid. My first step would be to verify calibration status and check when it was last calibrated and whether it’s due. Then I’d test the equipment against known reference standards or certified masters—if I have a micrometer giving questionable readings, I’d measure calibration blocks to verify. If the equipment fails verification, I’d quarantine it and notify the calibration coordinator for repair or recalibration. The difficult part is addressing what I’ve already inspected with that equipment—I’d need to alert my supervisor because we may need to re-inspect recent parts to ensure we haven’t accepted bad parts or rejected good ones. I’d document the entire situation in a nonconformance report so we can investigate root cause and prevent recurrence. Equipment accuracy isn’t something you can compromise on in quality control—it’s the foundation of everything we do.”

10. Where do you see your career progressing in quality, and what skills are you developing?

Why ask this? This reveals ambition, growth mindset, and long-term potential—you want inspectors who will develop into senior quality roles, not just remain entry-level forever.

Sample Strong Answer: “I’m passionate about quality and see myself progressing into quality engineering or quality management roles. I’m currently working toward my ASQ Certified Quality Engineer certification, which requires deeper knowledge of statistics, reliability, and quality systems design. I’m also developing my root cause analysis skills—I’ve been trained in 8D methodology and fishbone diagrams, but I want to get more practice leading corrective action investigations rather than just supporting them. I’m interested in supplier quality too, because I see how critical incoming quality is to overall product quality. Long-term, I’d like to lead quality improvement projects and mentor newer quality professionals. I’m also working on my communication and influence skills because as you move up in quality, it’s less about inspecting parts yourself and more about building quality into processes and influencing others to prioritize quality. I’m looking for an organization that values quality excellence and invests in developing quality professionals, not one that sees quality as just a cost center or compliance function.”

How CloudApper AI Recruiter Makes Hiring Quality Control Inspectors Effortless

Now here’s where quality talent acquisition gets truly revolutionary: imagine having an intelligent AI recruiting assistant that engages every quality control inspector candidate instantly—around the clock, every day of the year—asks these exact technical and behavioral interview questions (or your customized versions) via conversational text message, evaluates their responses for technical depth and quality mindset, and delivers a prioritized shortlist of qualified candidates directly to your quality managers with comprehensive assessment summaries.

That’s precisely what CloudApper AI Recruiter delivers for manufacturing organizations struggling to build and maintain world-class quality teams in an intensely competitive talent market.

Here’s how our conversational AI recruiter chatbot transforms quality control inspector recruitment:

24/7 Instant Technical Engagement

The moment someone expresses interest in your quality control inspector position—whether through Indeed, ASQ job board, LinkedIn, a QR code at a quality conference, or an employee referral—CloudApper AI Recruiter engages them immediately in an intelligent, natural conversation. No more losing certified quality professionals to competitors who respond faster. Our AI asks about their measurement equipment experience, GD&T knowledge, quality system familiarity, statistical methods understanding, certification status, and availability, then automatically scores responses based on your technical requirements and quality culture fit criteria.

SMS-First Screening for Quality Professionals

Quality inspectors work floor schedules, conduct inspections across multiple shifts, and attend to urgent quality issues—they’re not always available for traditional phone screens during business hours. CloudApper AI Recruiter meets candidates where they are by conducting comprehensive screening interviews entirely via text message. Candidates can respond during breaks, after shifts, or any convenient time, which increases completion rates to 86% (compared to 29% for traditional applications requiring computer access) and eliminates the candidate drop-off that undermines quality team building efforts.

Quality-Specific Technical Assessment

Our platform includes specialized question banks covering metrology proficiency, GD&T interpretation, ISO 9001 and industry-specific standards knowledge, statistical process control methods, root cause analysis techniques, measurement system analysis, CMM programming, and quality documentation requirements. You can customize questions for your specific industry (aerospace AS9100, automotive IATF 16949, medical device ISO 13485) and inspection technologies. The AI even presents scenario-based assessments—”You’re inspecting parts and notice measurements trending toward the upper tolerance limit. What do you do?”—and evaluates responses for analytical thinking, proactive problem-solving, and quality consciousness.

Bias-Free Evaluation Protecting Quality Standards

Every candidate receives identical questions asked with the same professional consistency, eliminating unconscious bias based on communication style, accents, educational background, or personal chemistry. CloudApper AI Recruiter evaluates responses objectively against technical competencies, quality mindset indicators, and integrity markers. This creates equitable hiring outcomes while ensuring your quality team comprises individuals who genuinely prioritize standards over convenience—critical for maintaining quality culture integrity.

Certification & Credential Verification

Quality roles often require specific certifications—ASQ CQI, CMM programmer certification, industry-specific quality credentials. Our AI automatically collects certification information, validates current status, captures credential numbers, and flags expired or missing requirements. This ensures only properly qualified candidates advance to manager interviews, saving countless hours of screening time and preventing late-stage disqualifications.

Intelligent Candidate Ranking & Quality Manager Alerts

As candidates complete their AI screening interviews, CloudApper automatically ranks them using weighted scoring criteria you define—perhaps metrology proficiency counts 35%, quality system knowledge 25%, analytical skills 20%, GD&T expertise 15%, and integrity indicators 5%. Your quality managers receive instant mobile notifications when exceptional candidates emerge, complete with interview transcripts, technical assessment scores, and hiring recommendations. The system can automatically schedule facility tours or hands-on assessment interviews—reducing your average time-to-hire by 74%.

Proven Results from Manufacturing Quality Leaders

A tier-one automotive supplier in Ohio recently implemented CloudApper AI Recruiter to rebuild their quality inspection team amid aggressive production expansion. Within 90 days, they reduced average time-to-hire for quality control inspectors from 71 days to just 19 days, improved technical qualification scores by 44%, and decreased 90-day turnover among new quality hires by 38%. Their small quality leadership team went from drowning in resume screening and phone interviews to focusing exclusively on hands-on inspection assessments and cultural fit interviews with technically pre-qualified candidates.

Their Director of Quality told us: “We were losing certified quality professionals to competitors who could move faster through the hiring process. The technical screening alone used to take hours per candidate—verifying their metrology skills, GD&T knowledge, quality system experience. CloudApper’s AI conducts those technical screenings automatically, consistently, and instantly. We’ve gone from chronically understaffed to having a pipeline of qualified quality talent ready to onboard. It’s transformed our ability to support production growth while maintaining our quality standards.”

Ready to eliminate your quality control inspector hiring bottlenecks and build the inspection team your operations demand? Discover how CloudApper AI Recruiter can transform quality talent acquisition from a constant struggle into a sustainable competitive advantage.

FAQ

Why are specialized interview questions essential for quality control inspectors?

Generic questions miss critical competencies like GD&T interpretation, statistical process control, advanced metrology, and integrity under production pressure required in modern quality roles.

What key skills do today’s quality control inspectors need?

Beyond basic measurement, they require CMM operation, statistical analysis, quality management systems proficiency, root cause investigation, regulatory knowledge, and strong communication for cross-functional collaboration.

How does CloudApper AI Recruiter solve quality inspector hiring challenges?

It provides 24/7 instant engagement via SMS, conducts technical and scenario-based interviews, scores responses objectively, verifies certifications, and ranks candidates—dramatically reducing time-to-hire and dropout rates.

Why do quality candidates often drop out of traditional manufacturing hiring processes?

Slow responses, inflexible scheduling, and lengthy applications frustrate busy professionals, causing high abandonment before screening completion.

How does AI improve fairness and consistency in quality inspector screening?

AI delivers identical questions to every candidate and evaluates based purely on technical depth, quality mindset, and job-relevant criteria, removing bias from personal factors.

What results have manufacturers seen using CloudApper AI Recruiter for quality roles?

One automotive supplier reduced time-to-hire from 71 to 19 days, improved technical qualification scores by 44%, and lowered 90-day turnover by 38%.

Stop Losing Quality Professionals to Slow, Inconsistent Hiring

The shortage of qualified quality control inspectors will intensify as manufacturing complexity increases and experienced professionals retire—but your hiring process can accelerate dramatically while improving quality of hire simultaneously. With CloudApper AI Recruiter, you’ll engage quality candidates instantly, assess their technical competencies thoroughly via intelligent conversation, and identify meticulous inspectors who will protect your brand reputation and elevate your quality culture.

These 10 interview questions provide the framework for identifying quality control inspectors who will excel in your manufacturing environment. But conducting these technical assessments manually through endless phone screens, scheduling gymnastics, and inconsistent evaluation is exactly what’s keeping your quality positions open for months while defect rates climb and audit findings accumulate.

Let AI handle the screening heavy lifting so your quality managers can focus on hands-on assessment, cultural fit evaluation, and getting qualified inspectors trained and productive quickly.

Book a demo of CloudApper AI Recruiter today and see firsthand how conversational AI recruiting revolutionizes quality talent acquisition. We’ll show you exactly how to customize the platform for your specific quality requirements, industry standards, and measurement technologies—and get you operational in days, not months.

What’s your biggest challenge in hiring quality control inspectors right now? Comment below and let’s discuss how AI-powered recruiting can solve your specific quality talent acquisition challenges and help you build the inspection team your operations deserve.

You might also like to read:

10 Crucial Interview Questions for Warehouse Workers & Picker-Packers (+ AI Recruiter Automation)

What is CloudApper AI Platform?

CloudApper AI is an advanced platform that enables organizations to integrate AI into their existing enterprise systems effortlessly, without the need for technical expertise, costly development, or upgrading the underlying infrastructure. By transforming legacy systems into AI-capable solutions, CloudApper allows companies to harness the power of Generative AI quickly and efficiently. This approach has been successfully implemented with leading systems like UKG, Workday, Oracle, Paradox, Amazon AWS Bedrock and can be applied across various industries, helping businesses enhance productivity, automate processes, and gain deeper insights without the usual complexities. With CloudApper AI, you can start experiencing the transformative benefits of AI today. Learn More

CloudApper AI Solutions for HR

- Works with

- and more.

Similar Posts

How cNPS Reflects Your Recruitment and Employer Brand

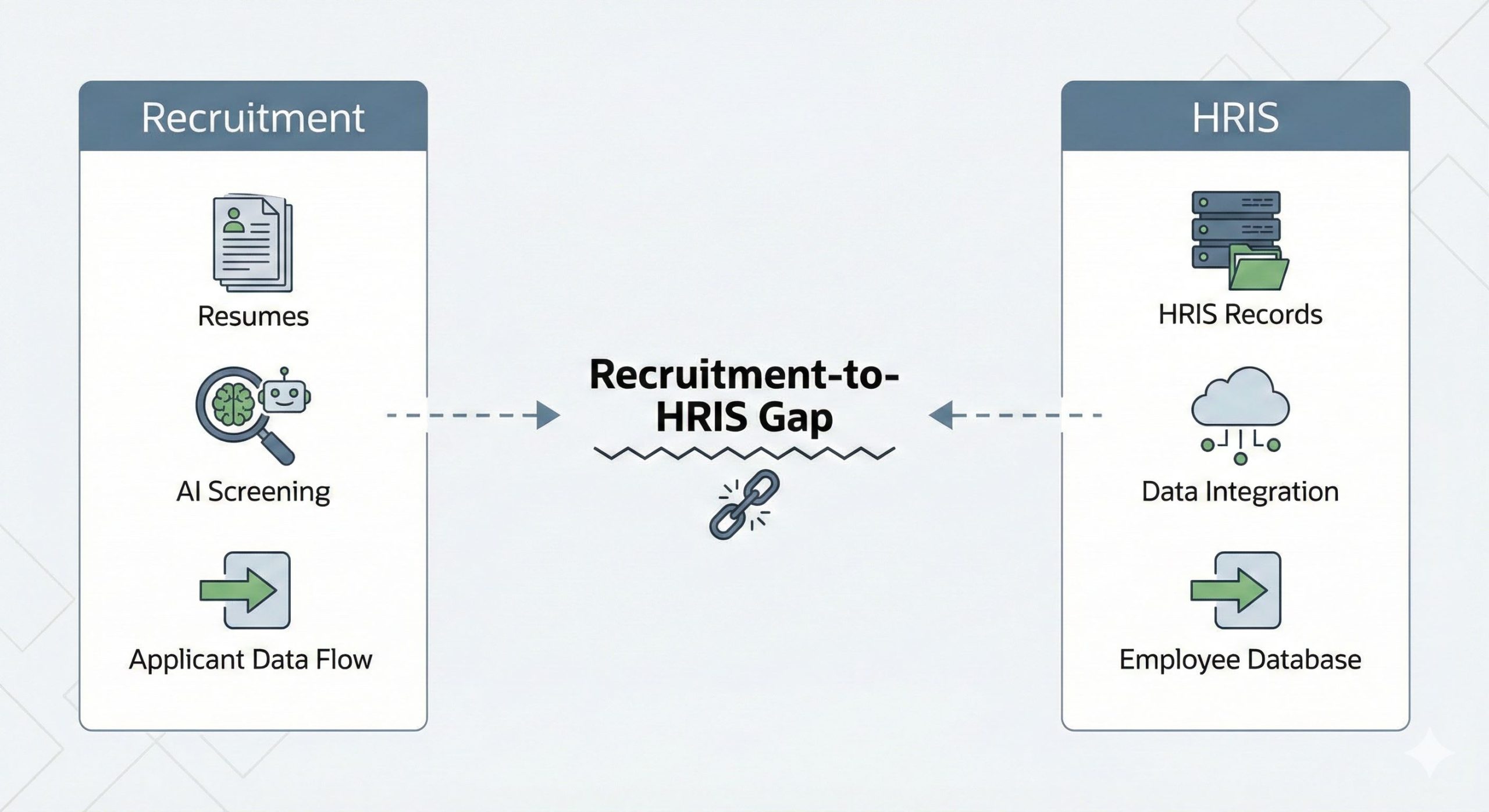

The Recruitment-to-HRIS Gap: Why Your “System of Record” Should Start…